Grinding of welding rollers is a critical maintenance procedure to ensure weld quality in metal container production. Soudronic recommends grinding the profile of the welding rollers after a production run of 1 to a maximum of 6 million bodies, or at least once a week.

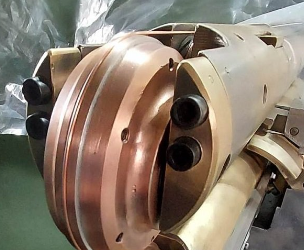

The grinding process involves removing the sheave from the machine, grinding it on a lathe to ensure that the profile corresponds to the technical specifications and then reassembling it on the machine. The outer contour of the welding rollers must also correspond to the specifications indicated in the welder’s manuals.

In addition, it is important to check and clean the lower welding roller after each shift because it is exposed to dirt, which is essential to maintain weld quality. The sheave should be checked for smooth running and to ensure that there are no hard or irregular parts that could block its movement.

For the Hg welding roller, the mercury level should be checked weekly and topped up if necessary. If the mercury level drops too fast or if leaks are detected, it is necessary to send the sheave and pendulum unit to Soudronic for overhaul.

In summary, the frequency of grinding of welding rollers depends on production and machine usage, but as a general rule, it should be performed at least once a week or after reaching a specific number of bodies produced, which can vary between 1 and 6 million.

0 Comments