INTRODUCTION

The equipment that is usually used in the metal industry almost always admit improvements in relation to the initial state supplied by the manufacturer of the machine. It is to a certain point logical, these teams are not like a car, of which hundreds of thousands of units are manufactured and are therefore studied to the last practical detail. The machines in the metal sector, except some very specific models, are not manufactured in large series, but one by one and on request and in many cases adapted to the specific requirements of the client. Therefore, the number of machines that are exactly the same can be very small. This usually generates models of equipment that is not “worked” and that later, during its use, expose its failures or limitations. It is the metalworker who detects these failures and who suffers it, often resulting in claims to the constructor that are not always well resolved. Many metal designers choose to improve their equipment, following a wide variety of processes, from which they leave everything in the hands of their production mechanics so that they can adapt to their taste and manner, even those who have a well-defined procedure with specialized human resources. it.

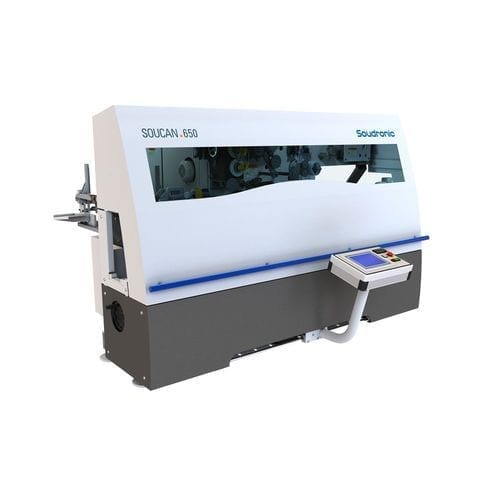

In this paper we intend to describe a simple and affordable procedure for everyone, to implement a procedure to improve any equipment, for example: a seamer or a gumming machine.

Take for example a seamer. Suppose that in a packaging manufacturing line, your closing machine is a conflicting equipment that directly affects the quality and production of the line. Therefore it is decided to put the means to remedy the situation. How to act?

RESPONSABLE

The first thing is to select a suitable person to study the problem and then pursue the implementation of the decisions taken. When we say a suitable person, we do not refer to a “superspecialized technician” in this machine. Must be a person with basic knowledge of the subject, but with certain skills of observation and order. A young trainee can be the ideal person, because he has habits of study, of taking notes, an open mind … It would suffice with an explanation of the problem and its objectives in a general way to get it going .. Whatever the person chosen, You must have enough time available during a season to dedicate yourself to this job.

PHASES

1ª.- DATA COLLECTION: The first phase consists of taking enough data for the concretion of the problems. It is not enough to know that the seamer goes bad, for example that it has many stops, you have to go into the precise details of the “why?”.

2 .- ANALYSIS: From the data collected, you need to study with an appropriate method what is happening, to get to identify precisely the problems.

3 .- DEFINITION OF SOLUTIONS: The next step once identified the problem is the search for appropriate solutions.

4th.- SETTING IN PRACTICE: Finally, you must start them.

DATA COLLECTION

We already have the person in charge prepared and the line in operation. You have to start your data collection. What data should you take? How much time has to be spent on this task? It will depend on each case, but generally we can say:

– You must do an audit on the machine for at least two weeks, about 80 hours of work. In this time it will focus on:

– Direct observations on the equipment, noting each stop time, its cause and its consequences, filling in a daily statement with these data. Annotation example: “Stop: 2 minutes. Cause: Catch a lid on the feeder. Consequences: Loss of 5 bodies and 3 caps (in addition to the loss of time) “

– Interviews with the mechanics and operators of the line – with all -. It will take notes of your observations, comments and opinions about what is happening and why.

– Collect all possible documentation of the progress of the line that can provide information about the problem:

– Daily parts of production and yields

– Parts of waste and waste line and of them those attributable to the seamer

– Parts of line quality and their rejections and of them those attributable to the seamer.

– Any other data available

These parties will collect a sufficient period of time, for example three months. If this information is not available or does not exist, you will have to make it at least for the duration of the audit of the seamer.

ANALYSIS

After the most exhaustive collection of data, a period of study and analysis is required. You have to start processing all this information. For this we begin by being clear that any failure actually translates into a “loss”. This loss can be of time (stops), of quantity of product (containers or damaged caps), of quality of product (production blocked for revision) etc. There is always a loss that has its economic value in all cases such as: decrease in production, increase in losses, time of revision, etc …

Therefore, we will begin this analysis by enumerating “the great causes of losses”. Generally they can be included in six types:

– 1.- Lost due to breakdowns.

– 2.- Lost due to preparation and adjustments (format changes)

– 3.- Lost due to minor stops and downtime

– 4.- Losses of start-up

– 5.- Losses of quality

– 6.- Lost for other reasons

We believe that your designation is clear enough and you do not need to explain what each of them consists of. In any case, later on, each one will be deepened.

We will take from the different line parts already indicated and from the audit carried out on the site, each one of the incidents and we will be imputing them to one of the defined losses. These incidents are possibly perfectly identified in the audit and will be more imprecise in the parts, but even so with patience and interest they can be classified.

After this classification of incidents by types of losses, a summary of all of them can be made and the economic valuation of each of the six losses in the period of time studied. To do this, it has been previously known the cost / time of the stop line (at least the direct labor) and the review of the production set aside as well as the standard cost of the containers that it produces The product of each consumption (” time / line “,” hours / man of revision “lost and discarded units) for its value, will give us an economic estimate of each loss.

Losses are classified by order of economic importance and so it will be defined which problems must be attacked first. They will be the ones that cause the greatest loss. Let’s continue with the example of the seamer. Let us suppose that the breakdown of the machine has been identified as a major loss. It will be necessary to make a list of faults that have been presented during the study time, adding the times of the repetitive ones. We will classify the partials in order of their magnitude and we will have a first list of problems to be solved properly weighted.

An analysis of each of these problems can give us a vision of what is happening. Let’s give some examples:

- a) If the breakdowns are of the type: shattered belts, broken chains, gears or worn sprockets, bearings in poor condition, axes with slack, etc … it is evident that the machine is evidencing a lack of sufficient and adequate preventive maintenance.

- b) If the one that breaks down is usually the same organ of the machine, it is that it is badly designed

DEFINITION OF SOLUTIONS

It’s time to seek the help of team connoisseurs. In an orderly manner and always starting with the problems identified as having the greatest economic impact, we must find a solution based on the specialists in the team in question.

Following with the previous example: Main loss, breakdowns in a closure and have already identified their different origins. It is about finding the right solution to each of them.

If the problem is due to lack of Preventive Maintenance, an adequate program will have to be established to do the same in the necessary time and manner. Maintenance specialists should develop the appropriate program.

If the problem is bad design of a certain organ, it will be necessary to redesign it.

Let’s take another example, continuing with our seamer. Let’s suppose that the second “loss” is for “preparation and adjustments”, that is to say for the excessive time spent in making a change of format or height in said closing machine. It will be required to study how we can reduce it. One way may be to prepare a series of tools and gauges that reduce the time used for the operation. For example, equip the machine with precision millimeter rules so that the height change is very short, or a gauge for each height that allows opening or closing the seamer to a physical stop. One (several) meetings with line mechanics may be the best way to develop small tools or tools to reduce time.

A procedure that usually gives good results to improve the times of change of format is to perform the following exercise:

– Video filming of a change

– Meeting of line mechanics to see and establish a sequence of elementary operations agreed among all to unify the procedure, eliminating unnecessary work and movement.

– Write sequence instructions of these agreed elementary operations.

– Make a practical test following the agreed procedure, filming it again.

– To repeat the meeting and “polish” the final exchange procedure, acquiring the commitment among all to fulfill it.

Similar path would have to continue with the search for solutions of the other losses. As far as quality is concerned, they are often caused by operations prior to the one that causes the problem, such as in the case of a seamer, the quality of the covers (out of measures, deformed, stuck by excess of compound, … )

Finally, it is the people who usually operate the machine together with imaginative mechanics or planners who can find simple and inexpensive solutions.

PUT INTO PRACTICE

The solutions found are still in motion. An improvement plan must be made, marking responsible, means and time to carry them out.

For the work to come to fruition, the motivation of the people involved is fundamental. It is frequent that those usually related in the work of these teams, see with some misgivings the intervention of others, considering that they can contribute little and that they themselves are in bad place if they detect points to improve. For this reason, it is essential that before starting work of these characteristics, there is a previous meeting where the task to be undertaken is positively approached and that it is seen as a success of all the results obtained.

0 Comments