The multinational company Ball, which has been located in Argentina since 1995, currently produces 2,000 million cans per year. The can was very well adapted to the form of marketing that existed in the pandemic, and it has remained thereafter. What was the cause?

The increase in can sales during the pandemic was due to increased home and on-the-go consumption. This was mainly influenced by the fact that the on-premise channel ceased to operate due to sanitary restrictions. For the same reason, during this same period, Ball was fundamental for craft beer producers, who had to move their sales to a home format, and there the aluminum can was an excellent solution for them, growing this format for the segment by more than 1000%. They needed a new sales channel and we believe Ball was a good partner to help them along the way.

In addition, the can has several attributes that make it an excellent choice. Today, consumers are increasingly looking to consume in a sustainable way, which benefits the can, as it is the most environmentally friendly packaging, being 100% and infinitely recyclable and with the highest recycling rate in the world. Apart from that, the can is also an excellent option for its practicality and convenience, since it is light, easy to carry, does not fragment, cools faster and preserves the original flavor of the beverages.

2.- What are the growth expectations for 2023?

We are in a global economic context affected by a contraction and inflation, and being a global company, we are not oblivious to this. So during 2023 we are readjusting our operation to make it even more efficient according to the scenario we are experiencing. So we expect a balancing of demand for aluminum cans, compared to the pandemic years, when it was incredibly high and accelerating. Now we will have a slightly less accelerated demand, and therefore our efforts will be focused on understanding it and adapting to a more organic growth of the format.

In this sense, our expectations are that demand volumes will tend to balance towards the pre-pandemic level. But we also expect to continue to grow in preference, driven by new categories such as wines, sparkling wines, ciders, ready-to-drink and coffee.

3.- What segments do you work with the most? Industrial beers, energy drinks and cocktails have experienced a very rapid increase. What other new products does Ball prepare?

Traditionally, beers and soft drinks are the easiest beverages to find in cans. But in recent years, we have made great strides in the use of beverage cans in a number of other categories. Today it is already possible to find many good choices of canned wines and sparkling wines, juices and teas, energy drinks, ready-to-drink beverages, coffees and even water, a sector that has shown great growth in countries such as Brazil and Chile, for example.

4.- What is the company’s investment plan for the future?

Our plan is to continue investing in innovation and sustainability. We have very strong commitments on these issues, which can be found in detail in our Climate Transition Plan. At Ball, we are committed to building a stronger business and a healthier planet, helping people live more sustainably, with sustainability as our business strategy. Our commitment, guided by the slogan “Towards the perfect circle”, aims to achieve zero emissions by 2050 and the use of 100% renewable electricity by 2030. Among its axes are:

True circularity: creating the perfect circle for our packaging products in which materials can be used in perpetuity.

Climate leadership: advancing climate science and achieving net zero carbon emissions by 2050.

Material health: ensuring that our products meet the highest material health standards to protect human health and the environment.

Resource efficiency: separating the growth of our business from the use of resources in our operations with a focus on the use of aluminum, energy and water.

Responsible purchasing: being part of a responsible and transparent value chain to grow our business and manage our risks.

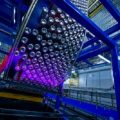

In addition to the above, we are launching Ball Digital Printing, a completely new printing technology in the market, which we will continue to invest heavily in this year. This new technology makes it possible to have labels with a multitude of colors, in photographic quality, with personalization and very fast delivery times for our customers, in addition to not requiring large volumes. We believe this technology will propel the can to the center of communication, as it allows the can to be used as a ticket for events, shows, special editions and much more.

5.- In terms of recycling, what projects are being carried out?

We have a very strong commitment to the sustainability of our products and operations. In the last year, for example, we achieved an overall average of 66% recycled content in cans, an increase of 3% compared to the previous year. As a result, in 2022, 87% (or US$13.37 billion) of revenues were generated from the sale of products that are made from recycled materials and are infinitely recyclable. These products include aluminum cans, cups and bottles, aerosol cans and laminates, which are other business segments that work with Ball worldwide.

Other parallel actions that we are very proud to be developing are:

Double ASI certification at our South American plants: The Aluminum Stewardship Initiative (ASI) is a global, not-for-profit initiative that defines standards to ensure sustainable performance based on environmental, social and governance (ESG) principles and provides assurance of responsible production throughout the aluminum value chain.

Social Bank of Cans in Chile: triple impact alliance that promotes the recovery of the beverage container with the highest growth potential in Chile. In 2022, more than 500 schools took on the challenge of collecting as many cans as possible in order to access environmental education programs and implement learning spaces. In 2023 we are going for a new edition.

QUIEROLATA + VADELATA: regional movement that is continuously engaged in communicating the benefits of aluminum packaging to consumers.

Ball’s sustainability department: Our company has a competent team specialized in issues related to the sustainability of our operations, our products and everything we are involved in. Globally, we work together in a committed manner to ensure that we are as sustainable as possible every day.

6.- What other advances in R&D as well as in digital printing can you advance us?

We continue to create with Digital Printing and develop campaigns and special labels with this technology. The idea is to be able to take full advantage of all the infinite possibilities that this technology brings to the printing of labels and canned products. In addition, we have several projects to reduce energy and water consumption throughout the manufacturing process of our cans. And when it comes to packaging, we are in the process of introducing an aluminum bottle in the near future. All of the above, with a view to better serve the requirements of our customers and, at the same time, to be responsible and sustainable with the planet.

0 Comments