To identify if the tinplate is of good quality, there are several factors and procedures that can be followed:

- Visual Inspection: A visual observation should be made both inside and outside of the tinplate containers, complemented with a photographic record to detect possible defects or inconsistencies.

- Quality Control at Reception: Upon receipt of the tinplate, the labels should be checked and the physical and chemical characteristics of the material should be tested. This includes verification of dimensions, detection of surface defects and possible pores in the lamination.

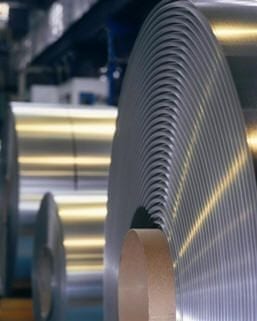

- Sample Analysis: Samples of tinplate should be taken at the beginning and end of each coil and analyzed in the laboratory for consistent quality control.

- Technical Specifications: The tinplate supplier shall ensure that the specification of the tinplate is suitable for the end use indicated. This includes aspects such as the level of passivation and the weight of the tin coating.

- Standards Compliance: The tinplate manufacturer should have quality procedures in place to ensure that each order meets established standards, such as ASTM or ISO.

- Corrosion Resistance Tests: Good quality tinplate should have high anti-corrosion properties, protected by tin and other passivation treatments.

- Verification of Tin Coating: The different types of tin coating should be identified and marked with parallel lines on one side of the tinplate.

- Surface Roughness: Surface roughness should be measured after chemically de-tinning the sample, and is performed at right angles to the rolling direction.

- Mechanical Characteristics: For certain uses, such as beverage containers, low gauge, double reduced tinplate can be specified to ensure adequate mechanical strength without high sterilization processes.

The combination of these practices helps to ensure that the tinplate used in container manufacturing is of the highest quality and suitable for its end use.

0 Comments