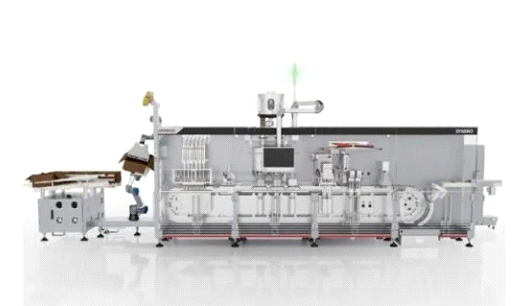

IMA Coffee presented a new machine with a high capacity to fill and close capsules in a very fast way, which was exhibited at Interpack. This machine was named SYNKRO.

Specifically, SYNKRO is a technological innovation that stands out for its improved performance, space efficiency and flexibility to handle all types of capsules, including those made of aluminum.

The structure of this machine is simple and compact, which greatly facilitates the maintenance and cleaning process. In fact, the removable dosing device is quickly cleaned when necessary. In addition, the size of the unit does not prevent it from achieving impeccable performance, with speeds between 800 and 1200 ppm.

When it comes to flexibility, SYNKRO is currently one of the most versatile and high-performance capsule filling and sealing machines available. The benefits of SYNKRO lie in the magnetic shuttles, which can be operated separately, making this system suitable for all types of needs. Whether bulk material such as trays or stacks, the size of the capsule does not matter; it is a flexible solution to all kinds of requirements.

It also offers users the possibility to choose from a wide variety of sealing systems to best suit their needs, either in terms of materials or the product being produced.

Both semi-automatic and fully automatic reel feeding are possible. Pre-set to connect to loading systems via AMR (Autonomous Mobile Robot), the machine also features an automatic reel splicing system. SYNKRO has also achieved a considerable improvement in the procedures related to capsule filling, as they have developed an innovative system that applies pre-compression to compress the coffee before inserting it into the capsule. This ensures that all finished products are homogeneous and have the same quantity in terms of dosage.

The exact weight of each capsule can be easily measured thanks to the in-line weighing system. This has the additional advantage that the data is automatically sent to the dosing unit, which minimizes the necessary adjustments. Finally, the off-set design of this unit makes the distance between capsules smaller, resulting in less material for packaging.

Increased competition has led coffee capsule manufacturers to seek higher yields, which has resulted in the development of SYNKRO, a tool aimed at satisfying the general market demand for filled and sealed capsules.

SYNKRO’s unique features make it superior to the competition. This includes independent magnetic transfer, synchronized and adjustable processing, automated and innovative mechanisms to ensure safe quality, as well as a clean and modular design.