The occurrence of displaced wings in the printing of aerosol bottoms may be due to several factors. Here are some possible causes and solutions:

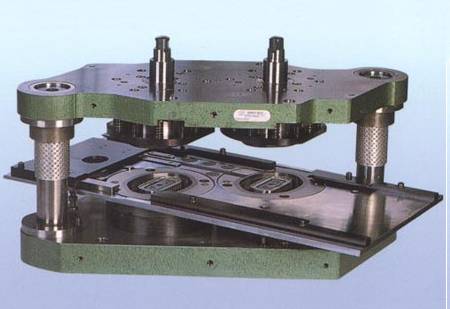

- Die wear or damage: Ensure that the die is in good condition and does not have excessive wear. If necessary, replace or repair damaged die parts.

- Incorrect die adjustment: Check if the die is correctly adjusted. Incorrect adjustment can cause stamping problems, such as displaced wings. Adjust the die according to the manufacturer’s specifications.

- Material thickness variations: The material used to manufacture the aerosol bottoms may have variations in thickness. Be sure to use good quality material with a uniform thickness to avoid stamping problems.

- Press speed: Press speed can affect stamping quality. If the press runs at too high a speed, it can cause problems such as displaced wings. Adjust the press speed according to the die and material manufacturer’s recommendations.

- Insufficient lubrication: Lack of adequate lubrication in the stamping process can cause problems in the formation of spray bottoms. Be sure to apply the proper amount of lubricant to the material and the parts of the die that come in contact with it.

If after reviewing and adjusting for these factors, the problem persists, it may be necessary to consult a die expert or the equipment manufacturer for additional advice.