Introduction

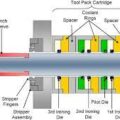

Rubber springs play a crucial role in the tool pack of can-making machinery. They are designed to dampen vibrations coming from the ram as it passes through the tool pack, resulting in better, brighter cans with fewer markings. This article will delve into the troubleshooting process for rubber springs in tool packs, ensuring that they function optimally and maintain the desired can quality.

Understanding Rubber Springs

The modern design of tool packs utilizes rubber springs and contoured pins custom-ground to the can maker’s die size. These rubber springs help absorb vibrations that could cause the die to mark the thin wall portion of the can as ribbing. As a result, the cans produced have a better appearance and quality.

Troubleshooting Rubber Springs

Visual Inspection Begin by visually inspecting the rubber springs for any signs of wear, damage, or deformation. If any of these issues are present, it may be necessary to replace the rubber springs to ensure optimal performance.

Check for Proper Damping Ensure that the rubber springs are effectively dampening vibrations from the ram. If the cans produced show signs of ribbing or markings, it may indicate that the rubber springs are not functioning as intended. In this case, further investigation is needed to determine the cause of the issue.

Assess the Contoured Pins Examine the contoured pins that work in conjunction with the rubber springs. If these pins are damaged or worn, they may not provide the proper support for the rubber springs, leading to reduced performance. Replace any damaged or worn pins to ensure optimal function.

Verify Die Alignment Ensure that the dies are correctly aligned within the tool pack. Misaligned dies can cause uneven pressure on the rubber springs, leading to premature wear and reduced performance. Adjust the dies as necessary to achieve proper alignment.

Inspect Air Blow-Off System The air blow-off system is essential for breaking the vacuum formed between the die and the surface behind it, allowing the rubber springs and suspension pins to return the die to the center. Check for any issues with the air grooves, air supply, or the lid that may be preventing the proper function of the air blow-off system. Resolve any issues found to ensure the tool pack operates as intended.

Conclusion

Rubber springs are a vital component of the tool pack in can-making machinery. By following the troubleshooting steps outlined in this article, you can ensure that the rubber springs function optimally, maintaining the desired can quality and appearance. Regular maintenance and inspection of the rubber springs, contoured pins, die alignment, and air blow-off system will help prevent potential issues and extend the life of your tool pack.