Introduction

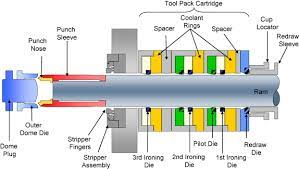

In the can making industry, the Tool Pack plays a vital role in the manufacturing process, ensuring that the cans produced are of high quality and free from defects. One of the most important components of the Tool Pack is the Rubber Springs. In this article, we will delve into the details of Rubber Springs, their function, and their importance in the can making process.

What are rubber springs?

Rubber Springs are specially designed components used in modern Tool Packs for can making. They are made of rubber and are designed to help dampen vibrations coming from the ram as it passes through the Tool Pack. Rubber Springs work in conjunction with contoured pins, which are custom ground to the can maker’s die size, to control die movement within the die modules.

Function and Importance of Rubber Springs

The primary function of Rubber Springs is to absorb vibrations that could cause the die to mark the thin wall portion of the can as ribbing. By dampening these vibrations, Rubber Springs help produce better and brighter cans. Here are some key aspects that highlight the importance of Rubber Springs in the Tool Pack:

Vibration Dampening: As the ram passes through the Tool Pack during the can making process, it generates vibrations. These vibrations, if not properly managed, can lead to defects in the final product. Rubber Springs effectively absorb these vibrations, ensuring that the dies do not mark the thin wall portion of the can.

Die Movement Control: Rubber Springs work in tandem with contoured pins to control die movement within the die modules. This precise control of die movement is crucial for maintaining the quality and consistency of the cans produced.

Improved Can Quality: By minimizing the impact of vibrations on the dies and controlling die movement, Rubber Springs play a significant role in enhancing the overall quality of the cans produced. The result is better, brighter cans with fewer defects.

Extended Tool Life: The use of Rubber Springs in the Tool Pack helps reduce wear and tear on the dies and other components, ultimately extending the life of the Tool Pack and reducing maintenance costs.

Conclusion

Rubber Springs are an essential component of modern Tool Packs used in the can making industry. Their ability to dampen vibrations and control die movement within the die modules contributes significantly to the production of high-quality cans. By understanding the function and importance of Rubber Springs, can makers can optimize their processes and achieve better results in their manufacturing operations