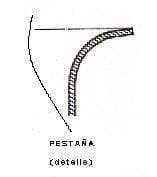

The flanges of tinplate food containers can crack due to several factors:

- Use of thin and hard materials: When thin and hard materials are used, the tampon flanging technique may result in breaks or cracks at the edge of the flanges, especially in small diameter containers.

- Lack of lubrication or waxing of the material: Inadequate lubrication during the flanging process can increase friction and cause cracks in the flanges.

- Worn or unsuitable tools: The use of worn or unsuitable flanging tools, such as those not made of tungsten carbide, can increase the risk of can flange cracking.

- Dimensional inaccuracy: If the container bodies have incorrect or non-uniform dimensions, this can cause difficulties during the flanging process and lead to cracks in the flanges.

To avoid cracks in the can flanges, it is important to use suitable materials, tools in good condition, ensure adequate lubrication and control the dimensional accuracy of the containers.

0 Comments