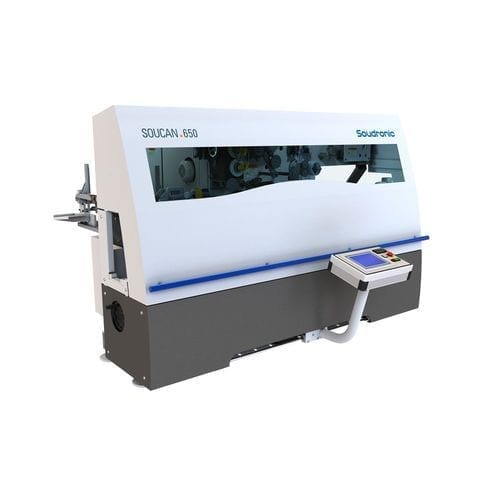

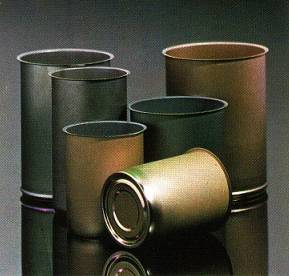

Butterfly welding, also known as “Butterfly” welding, is a welding method used in the manufacture of metal containers. This technique was introduced by Soudronic AG of Switzerland, with its semi-automatic electric welding sewing machines for tinplate. In this process, the side seams of the containers overlap by up to 4.5 mm, creating an appearance similar to that of a butterfly’s wings, hence the name.

However, butterfly welding is not suitable for food containers, as difficulties were encountered in varnishing the sharp edges of the seam. In addition, this technique is not as popular today due to its slow production speed compared to other welding methods.