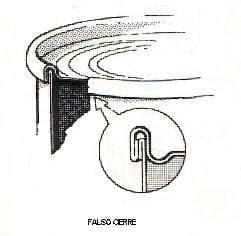

The mandrel on a can seamer plays a crucial role during the can seaming process. Its main function is to act as an anvil on which the rollers press when bending the flange and the flange in the formation of the hooks of the fastener. The mandrel can rotate on its vertical axis or remain static, depending on the type of riveting machine. However, it always remains in the same horizontal plane, i.e., it never shifts vertically.

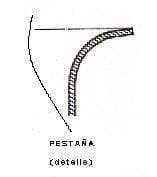

The mandrel dimensions also influence the shape and configuration of the seal. The mandrel consists of a shaft that serves as a support, with a flange or lip that fits the cap on the inside. This lip is slightly conical in shape to better fit the shape of the tray and to facilitate the ejection of the closed container.

The mandrel is constructed of tool steel, non-deformable, and is treated so that its lip has a high hardness. In some cases, for full can seamers, they are made of stainless steel. To increase its service life, it can be surface treated with titanium nitride or chromium carbide.