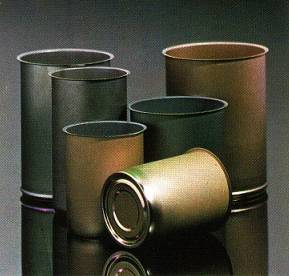

The causes of leakage in 3-piece containers can be varied. Some of the common problems that can cause leakage in these containers include:

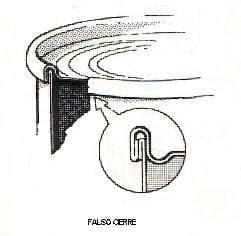

- Closure problems: In 3-piece containers, there are two closures, one at the top and one at the bottom. If any of these seals are not properly sealed, leakage may occur. The elimination of the bottom closure on stuffed containers reduces the risk of leakage by 50%. This also helps to:

- Reduce the risk of microbiological contamination by eliminating the seal.

- Simplify manufacturing by eliminating one operation.

- Weak weld: The weld joining the different parts of the container may be weak or have defects, which may cause leakage.

- Chubby flange: If the flange that joins the lid and the body of the container is not well formed, there may be leakage at the joint.

- Misalignment: If the parts of the container are not aligned correctly, there may be leaks at the joints.

- Inverted body: If the body of the container is placed upside down during manufacture, there may be problems in the joint and, consequently, leakage.

- Damage during transport or handling: If containers are mishandled or subjected to shocks during transport, they may be damaged and cause leakage.

- Corrosion: Corrosion of the container material, especially in the case of metal containers, can weaken the structure and cause leakage.

- Pressure variations: Sudden changes in pressure during the packaging or storage process can cause deformations in the container and lead to leaks.

- Low quality materials: If the materials used to manufacture the containers are not of good quality, they may be more prone to defects and, consequently, to leakage.

- Manufacturing defects: Errors in the manufacturing process, such as the use of improperly calibrated or worn machines, can lead to container defects and cause leakage.

To avoid these problems, it is essential to have rigorous quality control, use high quality materials and properly maintain production equipment. It is also important to train personnel in the proper handling of containers and to ensure that best storage and transportation practices are followed.

if their is loose seam on top even tho their is 20 mm gap possibility of leakage from the top