TOMRA’s next achievement will be the launch of the AUTOSORT™ PULSE, a processor with dynamic LIBS technology that handles high-precision sorting of aluminum scrap by alloy type, the new sorting system can be used in a wide range of applications to create high-quality secondary metals.

The metallurgical industry is currently trying to improve its recycling rates in order to save energy and avoid using new materials. To achieve this, the best sorting technologies are needed. The objective is none other than to recover pure mono materials from mixed scrap that can be processed into virgin material with high recycled content. Frank van de Winkel, pointed out in this regard that “Aluminum scrap consists of multiple alloys. Depending on the application, they contain a mixture of different alloying metals that define the material properties. To recycle a specific alloy without degrading the quality, it must be separated into specific alloy classes, a task that can only be accomplished with the most sophisticated technologies, such as LIBS.”

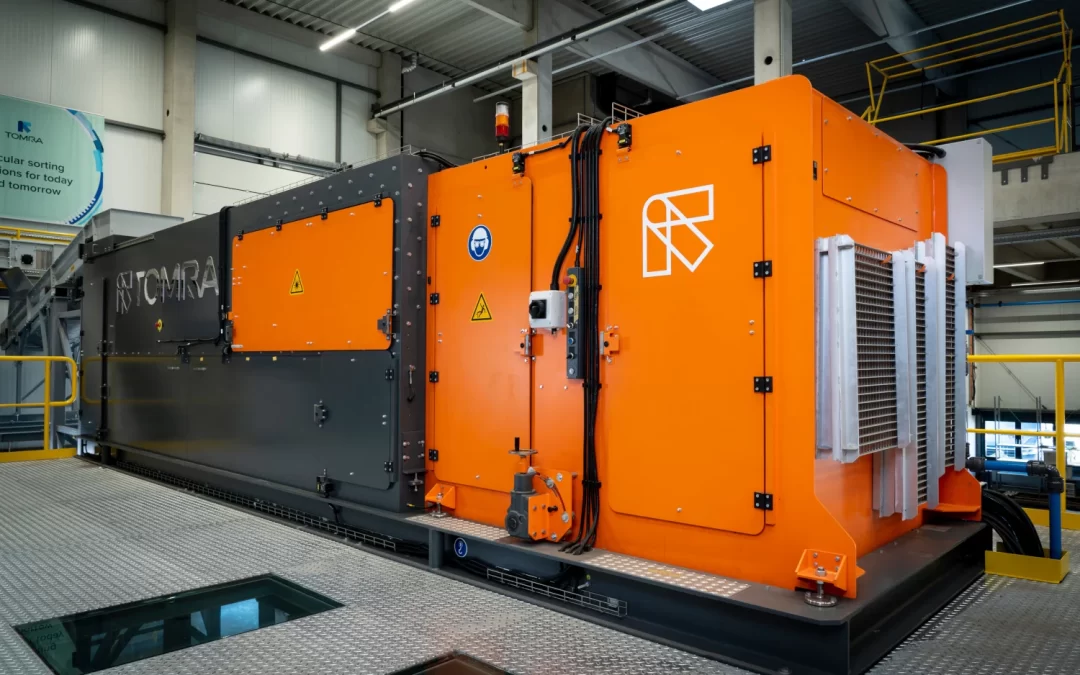

AUTOSORT™ PULSE combines state-of-the-art technology in a single machine, enabling the production of high-performance green aluminum. It offers exceptional performance in the separation of, for example, 5xxx and 6xxx aluminum alloys. The machine’s 3D object scanning detects every object regardless of its size and surface, while multiple single-point scans enable sharper detection of materials in any condition. Thanks to its AI-based object singulation feature, even overlapping and adjacent objects can be accurately separated to maximize performance.