Although the food packaging can has been used for more than 210 years, can manufacturers and the steel packaging industry are still optimising food cans and other tinplate packaging down to the last detail. Innovative container steel grades are the basis, process and geometry settings are the initial guidelines for the further development of the individual components. However, minor changes in the output material greatly influence the processability. It is necessary to adapt the machines and tools to the new material characteristics, as it is not possible to predict how the new container steel will behave under altered physical conditions, such as a reduction in thickness. And this is where a new approach in the packaging industry comes into play: the finite element method (FEM).

Thyssenkrupp Rasselstein, the only German tinplate manufacturer, no longer uses, as in the past, the costly “trial and error” method to test the use of innovative container steels, changes in container geometries or reductions in thicknesses; for several years now it has been using the finite element method (FEM) to simulate the tests virtually and efficiently. For this purpose, the German manufacturer has put together a team that helps its customers to intensify their efficiency. This makes optimizations faster and easier. “The finite element simulation makes it possible to optimise the geometry and processing virtually. The detailed descriptions of our container steels form the basis for product optimisations, both for the material and, in agreement with the customer, for the cans, lids or components. Optimizations can be implemented in a time- and resource-saving manner with this process,” says Dr. Manuel Köhl, Head of Applied Technology at thyssenkrupp Rasselstein GmbH.

DESCRIBE THE STEEL DOWN TO THE LAST DETAIL

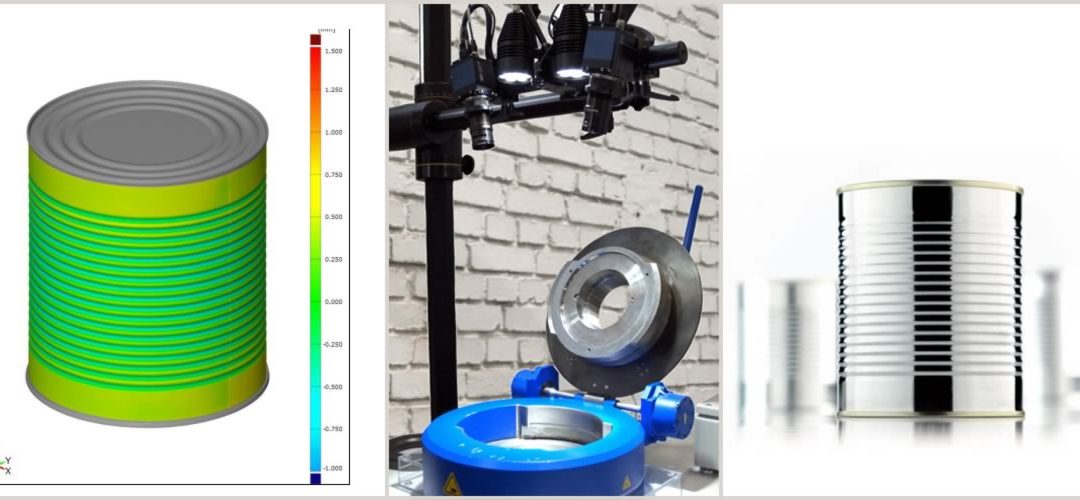

Accurate realistic simulation of the so-called material charts of container steel, with precise and extensive descriptions of the material characteristics. With the finite element method, for example, a manufacturer of food or aerosol cans will know, even before processing a thinner or innovative packaging steel, whether certain projects are feasible in practice.

“The development of steel for high-strength packaging has been a priority at Rasselstein in recent years. The rasselstein® Solidflex grade developed under this premise allows, for example, significant reductions in thicknesses for “easy-open” closures and for aerosol can components. This system is now being transferred to other grades, optimised especially for three-piece cans and also for DWI cans. For this product group in particular, we are testing how the new steels and the ribbed shapes optimised for them perform, taking into account the new thickness reductions,” says Köhl. However, the finite element method can be applied to all types of cans in general and to their components, such as aerosol can components, twist-off caps or crown caps.

The FEM-based system and its progressive application in new packaging steels not only saves resources by reducing the thicknesses achieved in this way, but also reduces CO2 emissions during transport. “In addition, the EMF enables products to be realised as projects and thus promotes innovation in the packaging sector. Manufacturers can dare to take on more ambitious projects and come up with more creative solutions,” says Köhl.

Thyssenkrupp Rasselstein now expands its database with available material charts and offers simulation with the finite element method as a service to its customers worldwide. Medium-sized companies in particular, which do not have the capacity for complex calculations, will benefit. “In this way, small and medium-sized companies can test designs and optimizations without incurring large costs. We also provide validated material charts to large companies for their own calculations, while offering them the service of product and process simulations by our FEM experts. It will save them time in the planning and product development phase,” explains Köhl.

FINITE ELEMENT METHOD WILL CONTRIBUTE TO SUSTAINABILITY IN THE SECTOR

With the FEM method, thyssenkrupp Rasselstein is using a technology that has already been applied in other high-performance sectors: “Up to now, FEM has mainly been used in the automotive sector; it is new in the packaging sector,” says Ioana Weinand. The development engineer is responsible for the implementation of the finite element method at thyssenkrupp Rasselstein and the application of simulation possibilities in customer and internal projects. The FEM team at Rasselstein is currently supported by a doctoral candidate, who is pushing forward the characterisation of packaging steels in a fundamental and scientific way in collaboration with the University of Erlangen.

The FEM is the centerpiece of a comprehensive digitalization strategy with which thyssenkrupp Rasselstein GmbH increases the efficiency and agility of its processes. “We are confident that the WEF will contribute to increasing the sustainability of the steel and packaging sector.

Soon, we will not be able to conceive the sector without the finite element method. We will therefore be concentrating even more on FEM in future, because we want to be at the forefront of the further development of this innovative technology,” emphasises Köhl.