Tata Steel has signed a contract with Tenova, a leading global metals technology manufacturer, to deliver a state-of-the-art electric arc furnace and additional advanced steelmaking equipment to its Port Talbot plant.

The company describes this agreement as a “significant milestone on the road to greener steel production.”

When operational from the end of 2027, the electric arc furnace (EAF) will reduce the plant’s carbon emissions by 90%, equivalent to 5 million tons of CO₂ per year.

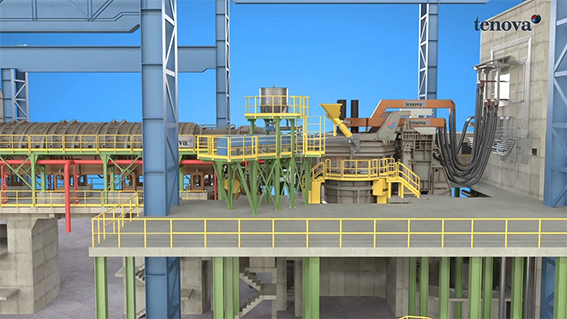

Tenova will supply an EAF with an annual capacity of 3 million tons of steel, similar to the plant’s blast furnace output, by melting steel scrap sourced from the UK. Tata said the use of scrap will also significantly reduce the UK’s dependence on iron ore imports, strengthening the resilience of UK manufacturing supply chains.

Narendran, managing director and chief executive officer of Tata Steel Limited, added that this agreement will allow the company to transform “our steel manufacturing plant, which will not only support the UK’s decarbonization pathway, but also provide economic development opportunities for South Wales. This will enable us to reduce the UK’s carbon emissions and support our customers in their own carbon reduction targets.”

The deal has been made possible by a joint investment of £1.25 billion by Tata Steel and the UK Government, with Tata Steel investing £750 million and the government investing up to £500 million.