FIMI was commissioned by the multinational Tata Steel to supply a high-performance cut-to-length and leveling line with an automated packaging system designed for high-strength strip steels.

At the Maastricht Service Center in Feijen, the Netherlands, a subsidiary of Tata Steel Nederland, work began on the installation of this new state-of-the-art, high-performance, high-performance leveling and cut-to-length line with automated packaging.

The move is part of Tata Steel’s plans to prepare for the growing future demand for premium abrasion-resistant and high-strength steels. It has the added advantage that thanks to the new uncoiling line, these steels can be processed faster, more accurately, with a wider window and in a more sustainable manner. The finished plates will be delivered to customers in Germany, Eastern Europe, the Benelux markets, the United Kingdom and the Nordic region. The new uncoiler, supplied by equipment manufacturer FIMI, is scheduled for commissioning in mid-2024.

The high quality of the finished plate will be possible thanks to the power of the new line, but also to a number of automated features, which make the process more sustainable. The new line will be highly automated facilitating high productivity in a very safe way. Automated functions and applications include: automated loading and threading, an automated robot tear-off unit, and automated thickness and dimension measurement.

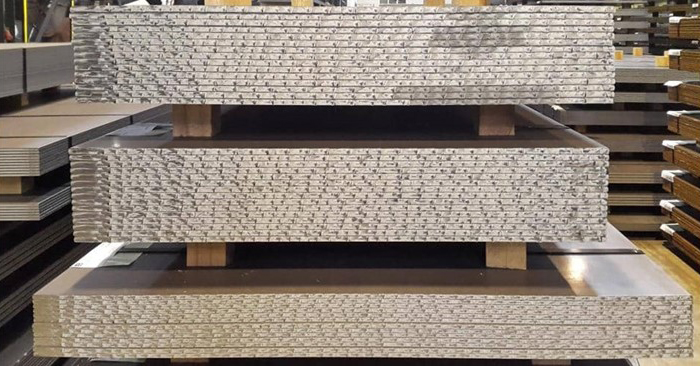

In addition, there will be automated sheet weighing and labeling, plus the advanced stacking technology includes an airbag system for noise reduction and shock absorption that ensures noise emissions are reduced to a maximum of 85 dB when sheets are stacked on top of each other.

At the heart of the line will be FIMI’s leveling technology: FIMI has developed a high-tech leveling process specifically for high-strength carbon steel material, based on the utilization of all levelers installed on the line. This system, due to a combination of bending and tension in the strip, guarantees a progressive and very efficient leveling performance from the inlet to the outlet of the line and minimizes the load on each individual leveler. Torque setting and distribution between the levelers is fully automated.

In this regard, Stig Eriksen, general manager of the Maastricht Service Center in Feijen, noted that the new decoiler line is of crucial importance: “With this real power, we are ideally positioned for the increasing demands for high-strength premium steels of the future and can grow in our target markets. Our goal is to continue to meet these market expectations in the future as the technical requirements for steel processing continue to increase,” the executive added.

Maddalena Aime, FIMI’s sales director, added that “thanks to its many years of experience in leveling and processing high-strength material, Tata Steel chose FIMI after evaluating several potential equipment suppliers. We are able to meet the technical requirements as well as the performance and quality levels demanded by Tata Steel in the best possible way. Reliability, competence, references and know-how play a decisive role in this. The new leveling and cut-to-length line is an ultra-modern line, designed not only for the present but also for the future. It is capable of processing ultra-high-strength material that is not yet available on the market.”

The new investment in leveling and cut-to-length lines, supplied by equipment brand FIMI, is part of Tata Steel’s strategic investment program in Europe and the Netherlands, which aims to better position the company to meet future growth in demand for quality steels. The investment program includes elements of the entire production chain, which extends from the steel foundry and the hot strip mill, and includes the cold mill, the galvanizing lines and the steel packaging plant.