Researchers from the IHSM-CSIC-UMA centers in Málaga and ICMS-CSIC-US in Seville have developed biodegradable lacquers from tomato pomace to coat the inside of cans and metal containers for food and beverages.

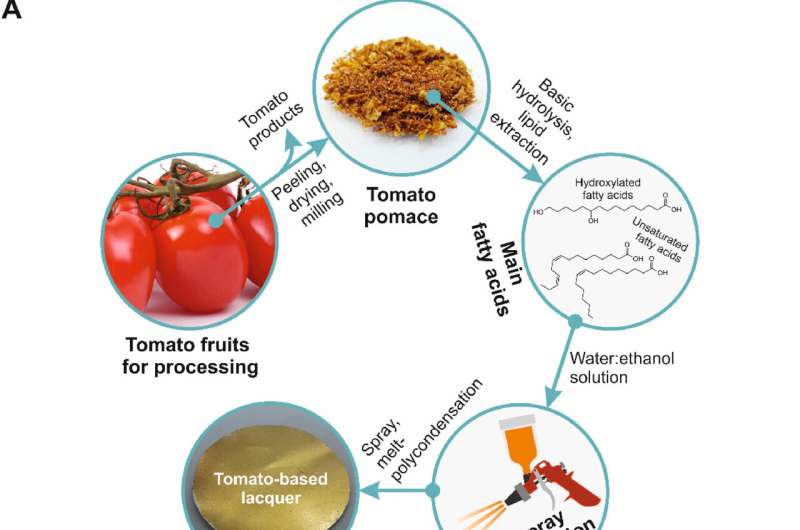

The new coating reuses by-products from tomato processing—seeds, skins, and stems—that are normally discarded or partially used as animal feed. After a drying and hydrolysis process, lipids are extracted from the pulp, dispersed in water and ethanol, applied to the metal, and subjected to heat polycondensation to form the resin.

The results show that this vegetable lacquer is water-repellent, adherent, and anti-corrosive, protects the metal against impacts or transport, and does not release compounds into the food, unlike BPA. In addition, its production generates less CO₂ and has a lower impact on human health compared to traditional resins.

After tests with food simulants, the next step will be to evaluate its performance with real foods such as crushed tomatoes, tuna, or other canned products, analyzing its stability during storage and sterilization.

This initiative represents a step towards the circular economy, transforming agricultural waste into a sustainable material that reduces dependence on fossil resources and waste generation.

Steel and aluminum containers require an internal coating to prevent corrosion and food contamination. Traditionally,