Coating problems in the manufacture of 2-piece cans can have important implications on the efficiency and profitability of a can manufacturing plant. It is not uncommon for plants to hold back several pallets of finished beverage cans due to problems detected during production quality control checks. With the rising costs of raw materials, energy, and personnel being experienced in the global economy in the wake of the pandemic, reducing these inefficiencies has become a priority. Reducing the number of pallets to be “held for inspection” (HFI) is a key cost reduction action for canmaking plants around the world.

There are many potential causes of metal exposure during the DWI process. These include poor gun coverage, gun failures or cans with little or no rotation on lacquer spray machines (LSM), washer contamination preventing lacquer adhesion, or even scratches caused during the collaring process. Whatever the source of the problem, it is imperative to quickly identify cans with high milliampere (mA) readings so that corrective action can be taken. Failure to do so will result in a backlog of cans that will need to be discarded or re-sprayed, and while re-spraying may be economically viable (compared to scrapping), this involves considerable disruption and additional work. In addition, if quality control fails to detect these cans, the consequences could be considerable and costly.

Having manual enamel grade gauges after IBO (LSM) and Necker (finished can checks) will certainly identify any potential coating problems. However, relying solely on manual enamel calibrators is susceptible to operator fallibility, which can influence the results obtained in enamel qualification tests. They can also be distracted by other tasks on the line, causing gaps in the testing process and delays in entering test results into the plant’s statistical process control (SPC) system. Failure to adequately check test variables, such as age and electrolyte resistance, can also affect the reliability of the results. In contrast, an automatic enamel tester provides repeatability and reliability, as the checks are performed continuously and consistently. The results are sent directly to the plant’s SPC system, allowing early detection of any high metal exposure problems and corrective action to be taken.

Tim Yeates, Sencon’s Far East sales director, commented, “Customer feedback has demonstrated the benefits of installing automatic enamel meters in the process. The system is set up to automatically sample about 8 cans at random every 10 minutes and the results are transmitted in real time. This continuous, consistent and rapid testing has reduced their HFI rates from metal exposure to about 2 pallets from the previous 10 pallets that were being retained for repainting or scrap.”

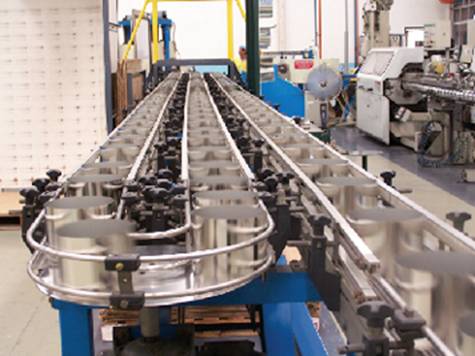

The Sencon Master Series™ fully automatic enamel tester (porosity tester) is a flexible, multi-line capable, modular system that offers a feature-rich environment that fully integrates with other testers in Sencon’s Master Series™ range. As an alternative to the feature-rich Master Series™, Sencon also offers the simplified and compact PG5600, which offers many of the advantages of Sencon’s Master Series™ enamel tester, but in a much smaller footprint and at an attractive price. Both meters are capable of consistently measuring metal exposure on modern, high-speed lines, allowing for early intervention and rapid adjustment should a problem arise. Electrolyte concentration, fill level and many other variables are continuously monitored, so users can be sure that the same reliable test quality is maintained day and night. With this consistency of testing, any trends or problems are quickly identified, allowing corrective action to be taken before excessive HFI or waste is generated.

The ability to detect problems early is a real game changer in metal exposure management and can easily lead to reduced overall costs, increased production efficiency and reduced customer complaints. Integrating automatic enamel calibrators, such as the Sencon Master Series™ or PG5600, is one of the best and easiest ways to ensure that these improvements occur and, more importantly, are maintained.