Description

Course “Quality Focused on Production”

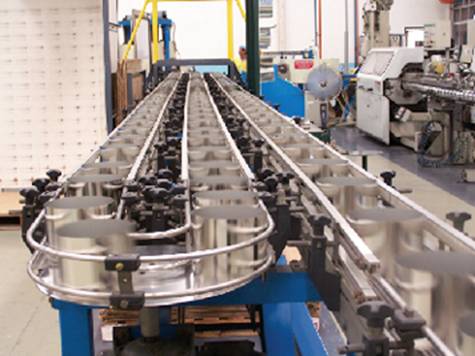

This course is designed to integrate quality concepts within the production process of tinplate food cans, with a practical and operational approach.

Critical control points during manufacturing are addressed: from sheet cutting, body forming, side seam application, double seaming, to final container inspection. The course teaches how to establish in-line controls, identify deviations, and apply timely corrective actions to avoid rework, efficiency losses, or risks of non-conformities.

It also analyzes the main process defects, their root causes, and how to implement continuous improvement tools to ensure a safe, standardized, and competitive product.

Highlighted Content:

-

Quality control at each stage of the production line.

-

Typical defects in bodies, lids, seams, and closures.

-

In-line quality parameters: inspection frequency and methods.

-

Documentation and records required by quality systems.

-

Preventive and corrective actions in production.

-

Role of quality as part of the production team.

Intended for: Professionals and technicians in the metal packaging industry, materials engineers, quality and production managers, and anyone interested in deepening their knowledge of raw materials used in this sector.

Methodology: The course combines theoretical sessions with practical case studies, allowing participants to apply the acquired knowledge to real industry situations.

Duration and mode: The course has a duration of 2 hours and is offered online, facilitating access to participants from different locations.

Language: Spanish

Certification: Upon completion of the course, participants will receive a certificate of achievement that accredits the knowledge acquired in raw materials for metal packaging.

Reviews

There are no reviews yet.