Description

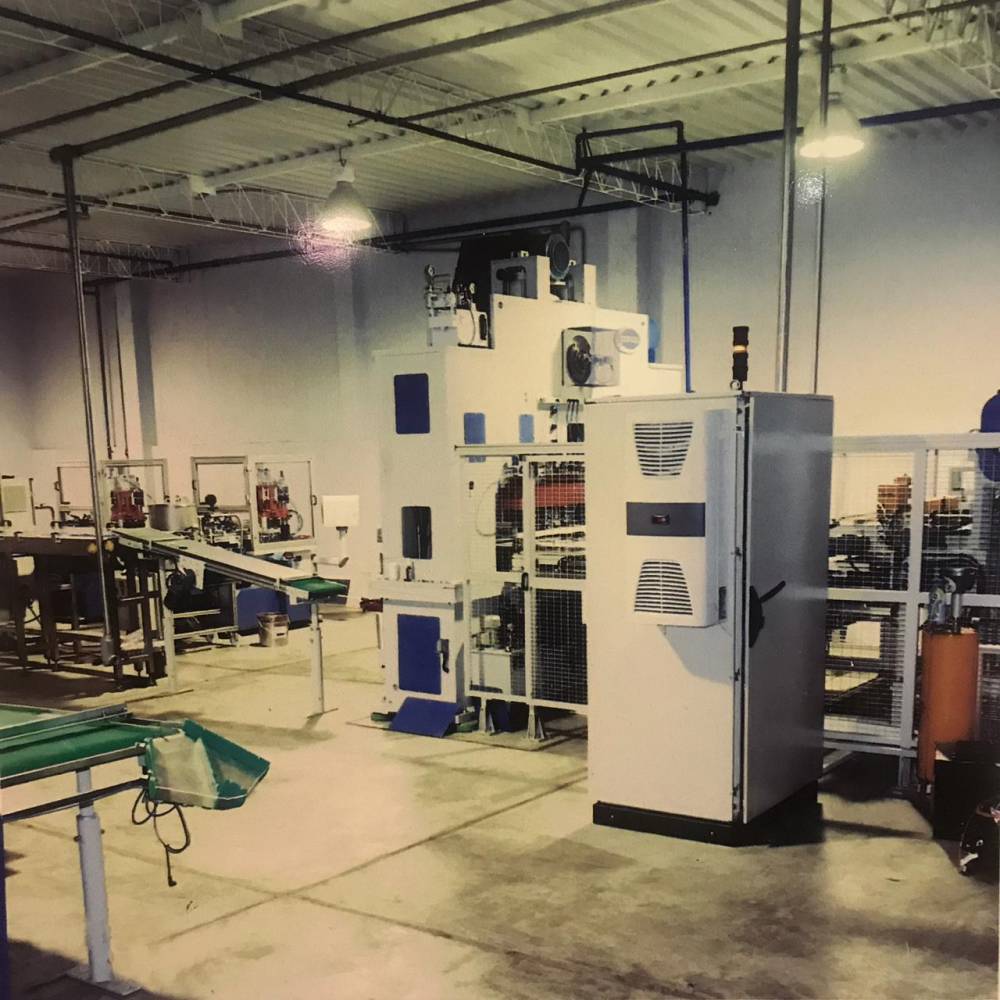

A complete manufacturing line, with tools for diameters 58,63 and 82 mm RTS / RSB with sheet feed press tools with 3 outlets each format and 2 MF8 and furnace, max. output 500 tpm.

TECHNICAL DATA:

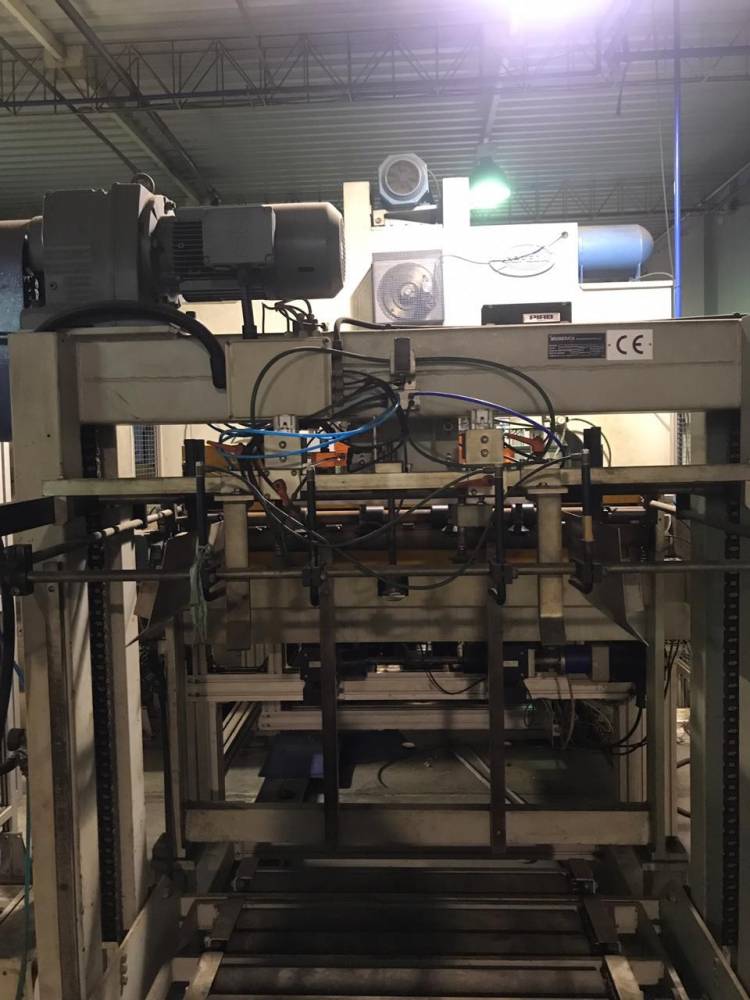

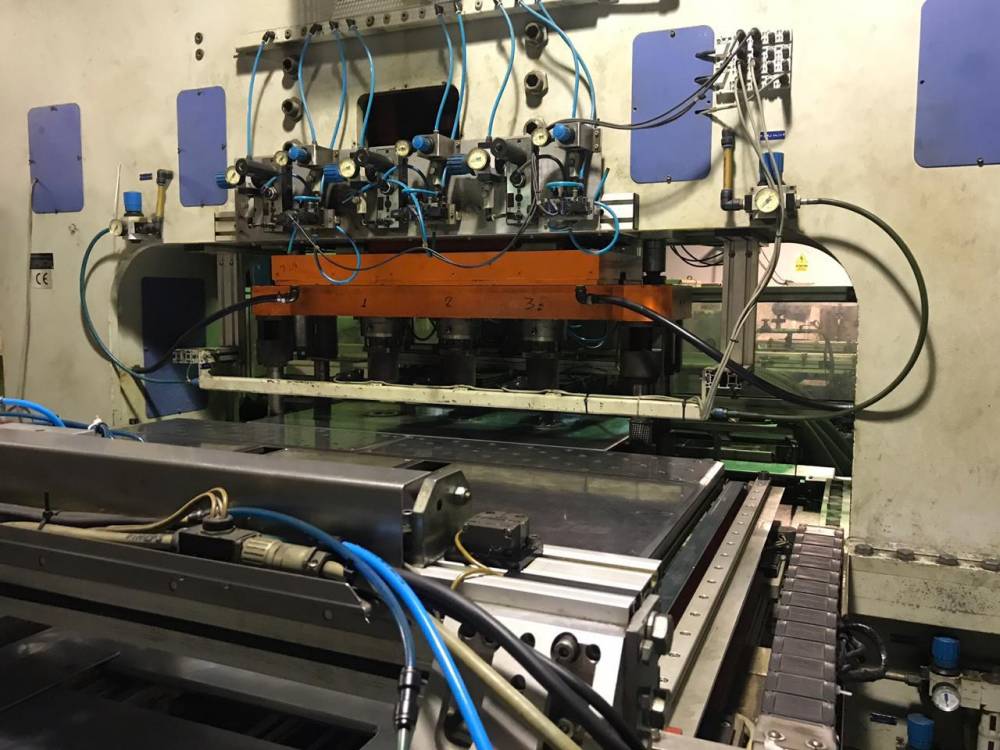

- Production line for rotary tumblers with full sheet pressing of 40 tns. With: pallet elevator and feeder, centering table, blade lubrication system, extrusion system and triple pneumatic cushion.

- 40 ton whole press

- Blade lubrication system

- X and YY axes of the linear motor-driven feed station (magnetic motors)

- Ejector system

- Triple pneumatic cushion

- 3-outlet die sets for 58 mm diameter formats

- 3-outlet die sets for 63 mm diameter formats

- 3-outlet die sets for 82 mm diameter formats

- Conveyor system between the 40-ton full-sheet press and the two rotary covers forming MF 8E

- Modulation forming press, MF 8E for rotary cups

- Infeed conveyor to the former MF 8E of approx. 1500 mm

- Extrusion conveyor of the former MF 8E of approx. 3000 mm

- Tools for 58 mm diameter formers.

- Tools for 63 mm diameter formers.

- Tools for 82 mm diameter formers.

- Pumping unit for MF 8E forming presses

- Transport between the 2 MF 8E and the drying oven.

- Sellacan drying oven for rotating cups

- Automatic lid counter

- Quality control and laboratory equipment.

- A set of tool-related spare parts

- Max. output: 500 epm

- Year 2006

Reviews

There are no reviews yet.