INTRODUCTION OVERCAPS FOR AEROSOL PACKAGING

The objective of this work is the definition of quality characteristics, reliability, inspection methods and acceptable quality levels for the covers destined for aerosols. The comments made here are applicable to all caps, overcaps, seals and special closures made of plastic for aerosol containers.

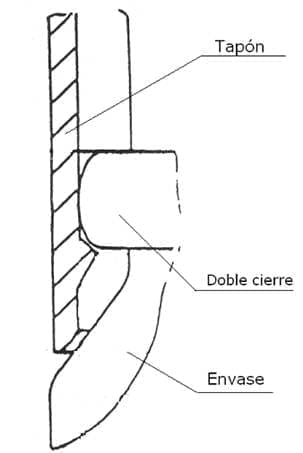

Figure 1 shows the connection between a plastic cap and the aerosol metal container. In this case it is a “3 pieces” type container, in which the fixing is made on the double closing of the dome and the body.

When the container is of the aluminum monoblock type, the fastening of the cap takes place on the clinching of the valve that is housed in the hole of the dome.

In any case, the cap forms a completely harmonious with the container, presenting a cylindrical appearance as a whole, with an almost equal outer diameter in both parts.

Figure nº 1: Fixation between cap and container

SUPPORT DATA OVERCAPS FOR AEROSOL PACKAGING

The standardized dimensions for standard plug models are based on:

– FEA 223 standard for spray bottle caps.

– FEA 201 standard for dimensions of the hole of the 1 “dome

– Standard FEA 214, UNE 49 – 356 for tin type aerosol cans and straight container.

– Standard FEA 218, 220 and 221 for aluminum aerosol containers (monoblock) with 25.4 mm mouth.

PROCESS OVERCAPS FOR AEROSOL PACKAGING

To analyze the Quality Control of aerosol caps, the following aspects must be considered:

– Packaging and identification

– Compliance with the technical specifications provided in each case.

– Compliance with functional specifications.

A.- Packaging and identification:

The pieces must be packed in corrugated cardboard boxes designed to protect the lids from possible deformations that may appear as a consequence of storage and transport.

All the boxes will be provided on the outside with enough information for their correct identification.

B.- Technical specifications:

The specifications that each supplied batch must comply with will be those accepted and agreed between the manufacturer and the user and that, in general, will adequately define the following parameters:

– Material: All the materials and colorants used will comply with the current Technical-Health Regulations, regarding the use of Polymeric Materials in relation to food products.

– Color : The intensity and tonality of the colored materials will be within the range agreed with the client through the relevant approvals.

– Decoration: The texts and marks will be those specified by the client in accordance with the homologations previously made.

– Dimensions: The dimensions will be those that will be specified in the plans accepted by both parties, or in accordance with the values set in the Standards for standard models. In the work published on dimensions of cupulas of aerosol containers fitted the fundamental measures to be taken into account in the design of these covers are indicated.

C.- Definition of functional characteristics:

The covers have to fulfill a series of characteristics in their operation. The definition of the same are the following:

– Vertical extraction effort: Force necessary to simultaneously make all the anchor points jump out of the container.

– Horizontal extraction effort: Force that applied on a generatrix of the lid and at a preset distance from the bottom of it is able to extract it from the container.

– Impact resistance: Vertical impact that is capable of supporting the lid mounted on the container without breaking.

The values of these functional efforts have to be fixed by both parties previously.

DEFECTS OF OVERCAPS FOR AEROSOL PACKAGING

A.- Classification of defects:

The defects, according to their importance, are classically classified into three different types:

– Critical: Are those that can lead to dangerous conditions or lack of security for the users of the container, cause confusion or doubt in relation to the content and those that prevent the processing of the product online.

– Older: They are those that affect the physical or aesthetic quality of the whole, or make the correct functioning of the container difficult.

– Minor: Are those that affect the physical or aesthetic quality of the whole in a slight way.

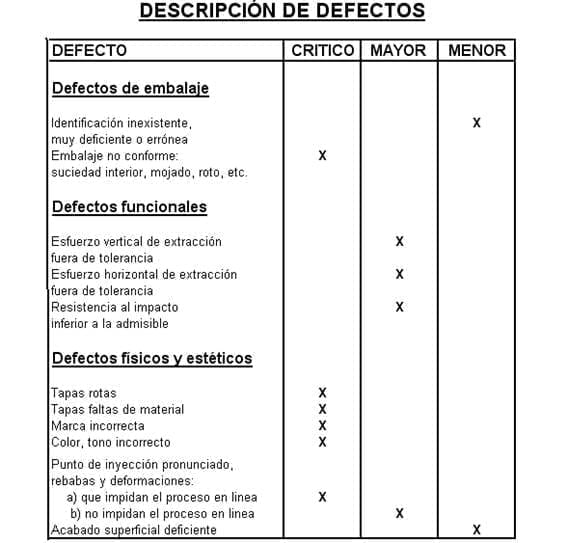

B.- Definition of defects:

The main defects are defined in the following list:

ACCEPTABLE QUALITY LEVELS OVERCAPS FOR AEROSOL PACKAGING

Acceptable quality levels are defined by the “AQL” agreed for each type of defect. Its use is specified by the “Military Standard” tables.

The levels of “AQL” adequate for each type would be:

Critical defects …………………………………………. 1.0

Major defects ………………………………………… 2.5

Minor defects ………………………………………… 6.5

0 Comments