Food and Beverage Metal Cans Market by Internal Pressure Grade

Key results

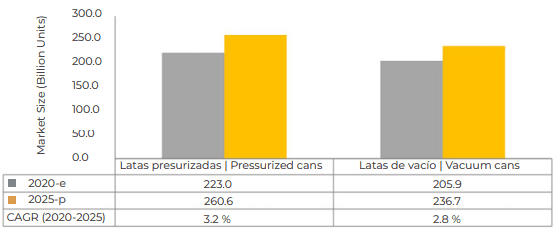

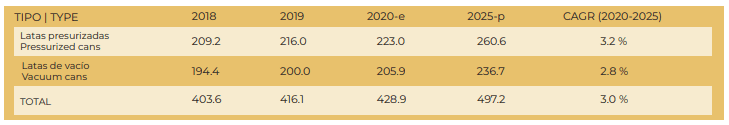

– The pressurized segment is estimated to dominate the metal food & beverage cans market and grow at the highest CAGR during the forecast period. It accounted for the largest share of nearly 51.8% in 2018 and is projected to reach 260.6 billion units by 2025.

– Rising consumption of carbonated beverages in developing regions, such as Asia Pacific and South America, has spurred the demand for pressurized cans, as these beverages require proper packaging to maintain their fizz and taste.

Introduction

For the purpose of this study, two types of metal cans are considered according to their degree of internal pressure, namely, pressurized cans and vacuum cans. Both types have wide applications in the food and beverage industry. Vacuum cans are mainly used for milk drinks, seafood, sweets and bakery products. Carbonated beverages and beer are therefore increasingly being used in pressurised cans. However, with changing consumer trends and the evolution of packaging technology, vacuum and pressurized cans play an important role in the food and beverage packaging industry.

FOOD AND BEVERAGE METAL CANS MARKET SIZE, BY INTERNAL PRESSURE GRADE, 2020 VS. 2025

FOOD & BEVERAGE METAL CANS MARKET SIZE, BY MATERIAL, 2018-2025 (USD BILLION)

On the basis of internal pressure grade, the pressurized cans segment dominated the metal food & beverage cans market in the market and is projected to grow at the highest CAGR during the forecast period. This is attributed to the high quality packaging solutions provided by pressurized cans for carbonated and non-carbonated beverages. These cans help to maintain the flavour and quality for longer. In addition, the structure of the pressurized cans makes them efficient enough for consumers to hold and carry.

Pressurized cans

REDUCING THE WEIGHT OF CANS IS A COST-EFFECTIVE ALTERNATIVE FOR TRANSPORTATION

Pressurized cans are the most preferred in the beverage industry. It is widely used for carbonated beverage, beer and fruit juice. In pressurized cans, the carbonated gases are filled under pressure in the container. These gases develop a high internal pressure inside the can compared to atmospheric pressure. Therefore, due to the increased pressure, most of the liquefied propellant is converted into gases. Therefore, making the cans light and efficient for logistics. Carbonated gas is effective in maintaining the effervescence of beverages until it is opened. Therefore, pressurized cans are expected to experience significant growth in the beverage industry. The 2-piece cans are mainly filled under pressure, as they find applications in the beverage industry.

Vacuum cans

INCREASE IN THREE-PIECE CAN APPLICATIONS IN THE FOOD INDUSTRY TO DRIVE VACUUM CAN BRAND GROWTH

Vacuum cans are preferred for packaging food and beverage products such as milk, tea, coffee and fruit juices. Oxygen has oxidizing properties; therefore, in food cans, it enhances the chemical degradation and microbial spoilage of many foods. However, vacuum cans help preserve food longer and overcome the effects of oxygen. In these cans, the pressure inside the can is less than atmospheric pressure. Therefore, it helps to extend shelf life, enhance flavors and retard bacterial growth in foods. Vacuum packaging removes the air from the package and produces a vacuum inside. These cans generally have flat shaped ends. The main strength of vacuum cans is their rigidity. The 3-piece cans are mainly vacuum packed, as they have wide applications in the food industry.

0 Comments