Food & Beverage Metal Cans Market By Type

Key results

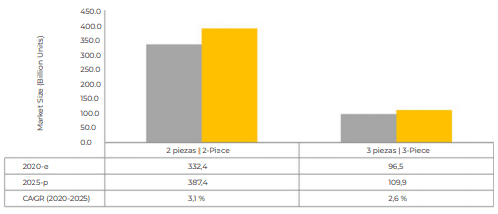

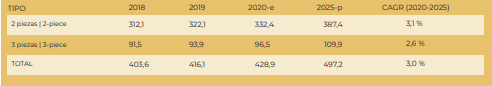

– The 2-piece segment is estimated to dominate the metal food and beverage cans market with a share of around 77.3% in 2018, and is projected to reach 387.4 billion units by 2025, at a CAGR of 7.1% during the forecast period .

– The demand for canned food and beverages from developing regions such as South America and Asia Pacific has contributed to the demand for 2-piece cans, especially for carbonated beverages that have an extended shelf life.

– 3-piece cans are used for food packaging and therefore represent a smaller market share compared to 2-piece cans which are mainly used for beverage packaging.

Introduction

For this study, two main types of packaging cans are considered according to the number of components that make up the final structure: 2-piece and 3-piece cans. Both types have wide applications in the food and beverage industry. Cans find their application mainly in the beverage industry due to the increasing consumer demand for alcoholic beverages and carbonated soft drinks. These cans have the ability to preserve the taste and nutrition of your products for several years. The increase in disposable income resulted in significant growth of the metal food & beverage cans market. The manufacturing process of 3-piece cans is more complex and requires more raw materials compared to 2-piece cans. However, these factors are responsible for the preference of 2-piece cans over 3-piece cans.

Metal containers are considered one of the most reliable types of packaging for food and beverages. This helps to maintain the taste, quality and shelf life of the product. Most common beverages such as tea, coffee, beer, alcohol, carbonated soft drinks and fruit juices require metal containers to maintain their authentic taste. Metal packaging provides convenient and protective packaging, allowing for safe storage of food products.

FOOD & BEVERAGE METAL CANS MARKET SIZE, BY TYPE, 2020 VS. 2025 (BILLION UNITS)

FOOD & BEVERAGE METAL CANS MARKET SIZE, BY TYPE, 2018-2025 (BILLION UNITS)

Due to the various advantages of health benefits and preserved freshness, the demand for canned food and beverages is increasing worldwide. The 2-piece metal cans dominated the food & beverages market; this segment is projected to grow at a higher CAGR during the forecast period, owing to the safer packaging solutions provided by 2-piece metal beverage cans as compared to other packaging solutions such as Tetra Pak and plastic bottles.

cans of 2 pieces

GROWTH IN DEMAND FOR 2-PIECE CANS

DUE TO ITS ECONOMIC STABILITY IN THE MARKET

Two-piece cans are mainly of three types: deep drawing (shallow drawing) whose height is less than its diameter, drawing and re-drawing (DRD) and drawing and drawing (D&I). A 2-piece can consists of two components: an integrated body with a bottom lid and an opening lid. Two-piece cans require a technique called double stitching to join the can body with can lids to protect the contents from external contamination. Steel and aluminium are the raw materials most commonly used for the manufacture of this type of cans. These cans are suitable for filling carbonated and non-carbonated beverages such as beer, wine, sports drinks and fruit juices. 2-piece cans have several advantages over 3-piece cans, such as the can body has no side seam between the body and the bottom end; therefore, the can is hermetically sealed with less consumption of raw materials. The manufacturing process of 2-piece cans is simpler and more efficient than that of 3-piece cans. In addition, the 2-piece food cans are lightweight and are available with a stackable function, as a result of which they can save shelf space. With packaging technology continually evolving, the structure of cans has also been improving with a seamless can body and ease of printing on full cans; therefore, it is estimated that 2-piece cans will replace 3-piece cans.

Cans of 3 pieces

NTIAL CRITICAL GROWTH POWER FOR CANS

3-PIECE DESPITE LOW USAGE IN THE PAST

A 3-piece can consists of three components, namely, a bottom lid, a cylindrical body and a top lid with an opening. The 3-piece cans consist of a cylindrical body rolled from a piece of flat metal with a double-ended seam. Welded cans and soldered cans are two types of 3-piece cans. They are available on the market in different shapes and sizes. Steel is used for the manufacture of 3-piece cans because aluminium is not a suitable material for welding. Normally two types of steel are used for the manufacture of cans: type L and type MR. Type L is used for packaging highly corrosive products such as apple juice, berries and pickles, as it is corrosion resistant. The main applications of the 3-piece cans are now limited to the packaging of dried fruits and vegetables, milk powder, sweets. However, in recent decades, the growth potential of 3-piece cans is critical due to the evolution of 2-piece can manufacturing technology. Therefore, the 2-piece cans economically meet the growing demand of the food and beverage industry. The 3-piece cans are now available with 3D printing technology, to catch the attention of consumers and result in a relentless sale.

0 Comments