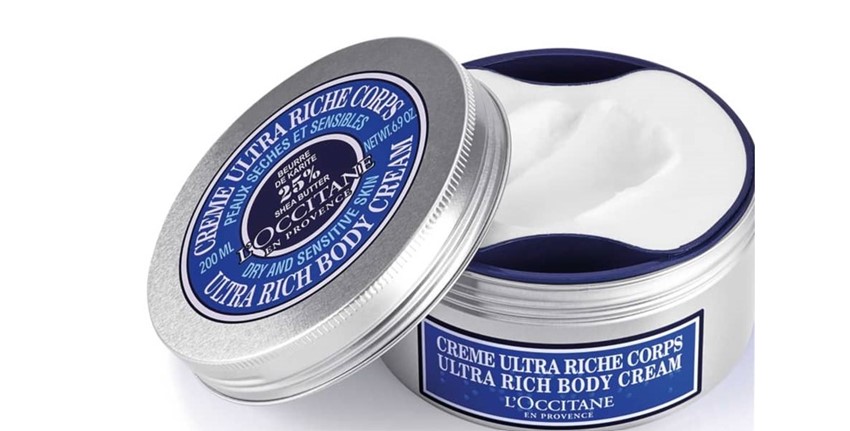

L’Occitane en Provence has always been committed to reducing the environmental footprint of its packaging and also maintains its commitment to the circular economy. As early as 2008, it launched its first eco-filler. Now, French plastics specialists VPI are going to carry out an ambitious and innovative project to manufacture new refills for Shea products: to create a new type of packaging for the “ultra-rich” body fluid.

The products are made according to eco-design principles and the Shea Body Cream meets several requirements that minimize its environmental impact. In addition, the L’Occitane teams decided to use a 100% PCR (Post-Consumer Recycled) PP material. This involves the reuse of fossil resources as well as the creation of a circular economy that benefits the recycling sectors and reduces the environmental footprint of the entire supply chain thanks to the inherent lightness of the material.

Seeing the importance of this product, VPI has achieved a technological breakthrough with the use of 100% recycled PP. The creation of the bathtub represents a real breakthrough since this action was previously impossible. That is nothing compared to having managed and ensured the traceability of the recycled material batches, produced the 200 ml volume container and done it all in a short period of time.

Through some good research, it was discovered that it would be a good thing for a handle to have a release and re-release latch. In addition, the design of the handle had to be studied in order to make it as easy as possible for the user to move the product.

This jar has a content of 200 ml and has a mechanism that seals it automatically. When it is the first purchase, it contains aluminum; however, after that, it will be made only for recharging.