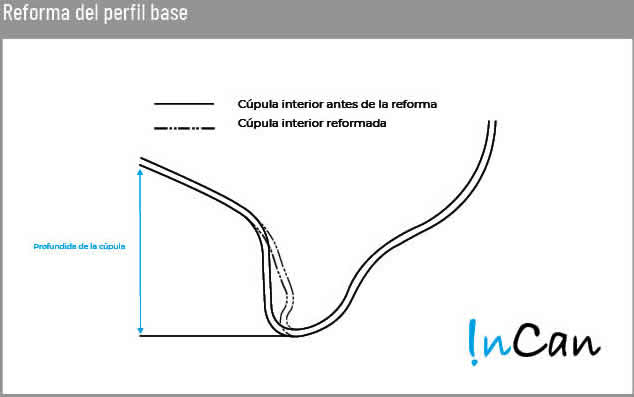

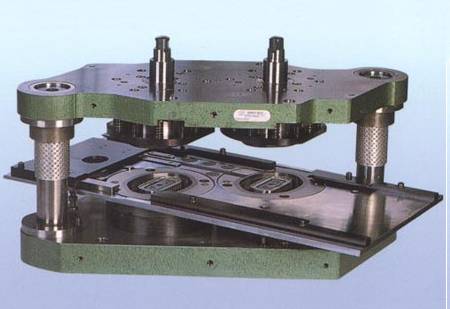

This process of reforming the dome on the inside is typically done after the flange is formed on the can. The Dome Internal Reforming module is part of the Die Necker train, this internal reforming process is used to control the growth of the dome and

increase its resistance to reversion.

increase its resistance to reversion.

The specification set by can customers for dome reversion is a minimum of 90 PSIG, when low metal gauges are used is when this inner dome reforming process is required.

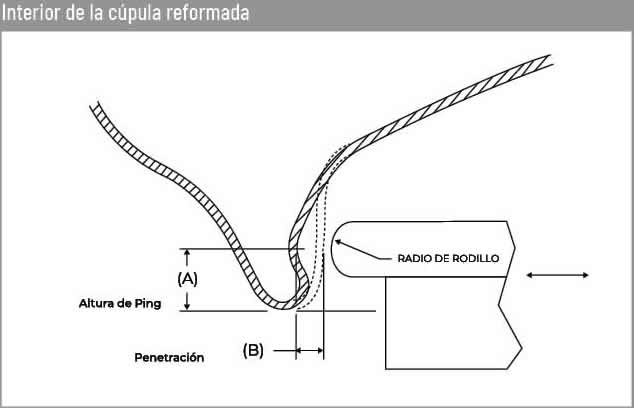

The tool used to reshape the dome will make a move on the vertical transition wall to the dome, where its location on the wall (Pin height) and the penetration made (Penetration) play a critical role in this operation.

The base former makes an indentation on the inside of the can dome to reduce the tendency of the support radius to uncoil under internal pressure.

Dome reforming controls dome growth during pasteurization and increases dome reversal pressure (DRP).

0 Comments