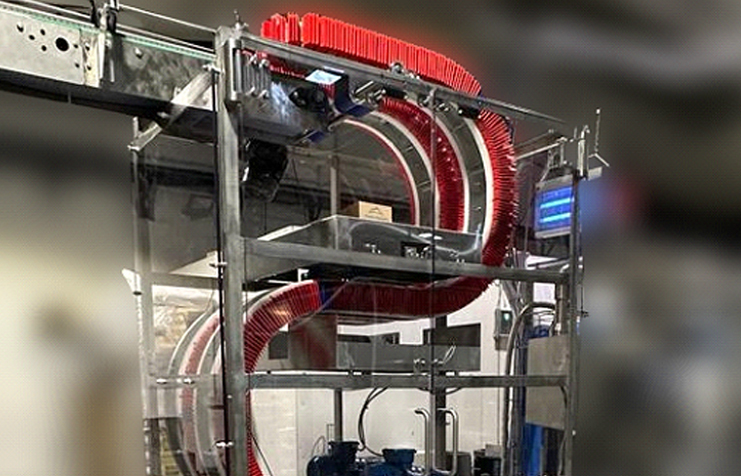

In January, Innovus Engineering delivered the first of its newly developed LWR-F downhill machines. A lowering device is an adaptable and cost-effective alternative to using a rotating device to move cans from a depalletizer to the canning machine. The key advantage is that switching between standard, slim and sleek cans takes just seconds, without the need for tools, a task that would otherwise involve changing expensive and fragile cans, a complex and time-consuming task, especially when there is production pressure. ! The LWR-F features inverter-driven motors for adjustable speed control and incorporates a can rinser, drip tray and drain hose to further increase line automation. As with all Innovus products, the construction is all stainless steel, with Siemens controls and machined food grade plastic components. A polycarbonate housing with safety lock keeps operators safe and protects the machine from dirt ingress. Contact Innovus at +441903331566 or sales@innovusengineering.com for more information.