The company Industrial Physics has introduced two automated machines to the market aimed at improving quality control in metal packaging production. These are the Torus Z606 model for inspecting embossing on lids and the Torus Z345 model for automatic color and design analysis on decorated cans.

These instruments, developed by the specialized brand Torus—integrated into Industrial Physics’ portfolio—respond to the current industry needs in terms of precision, efficiency, and automation. Thanks to their advanced technology, these solutions allow manufacturers to address key challenges in an increasingly competitive environment.

With the sustained increase in global demand for metal packaging expected until 2025, producers face the challenge of reducing waste, controlling costs, and increasing efficiency. A recent study by Industrial Physics indicates that over 40% of food and beverage packaging professionals are considering incorporating innovative technological approaches in the next three years. In this context, the new Torus models are presented as strategic tools.

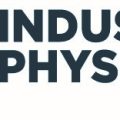

One of these tools is the Torus Z606, which provides automated embossing measurement on lids

The Z606 gauge has been designed to evaluate with high precision the residual embossing on can lids, an essential aspect to ensure ease of opening for the consumer. The automated, non-contact, and human intervention-free inspection eliminates potential operator bias and improves both efficiency and consistency of results.

Among its advantages is the possibility of performing programmed measurements at specific locations, allowing production plants to maintain uniformity in their quality control procedures on an international scale.

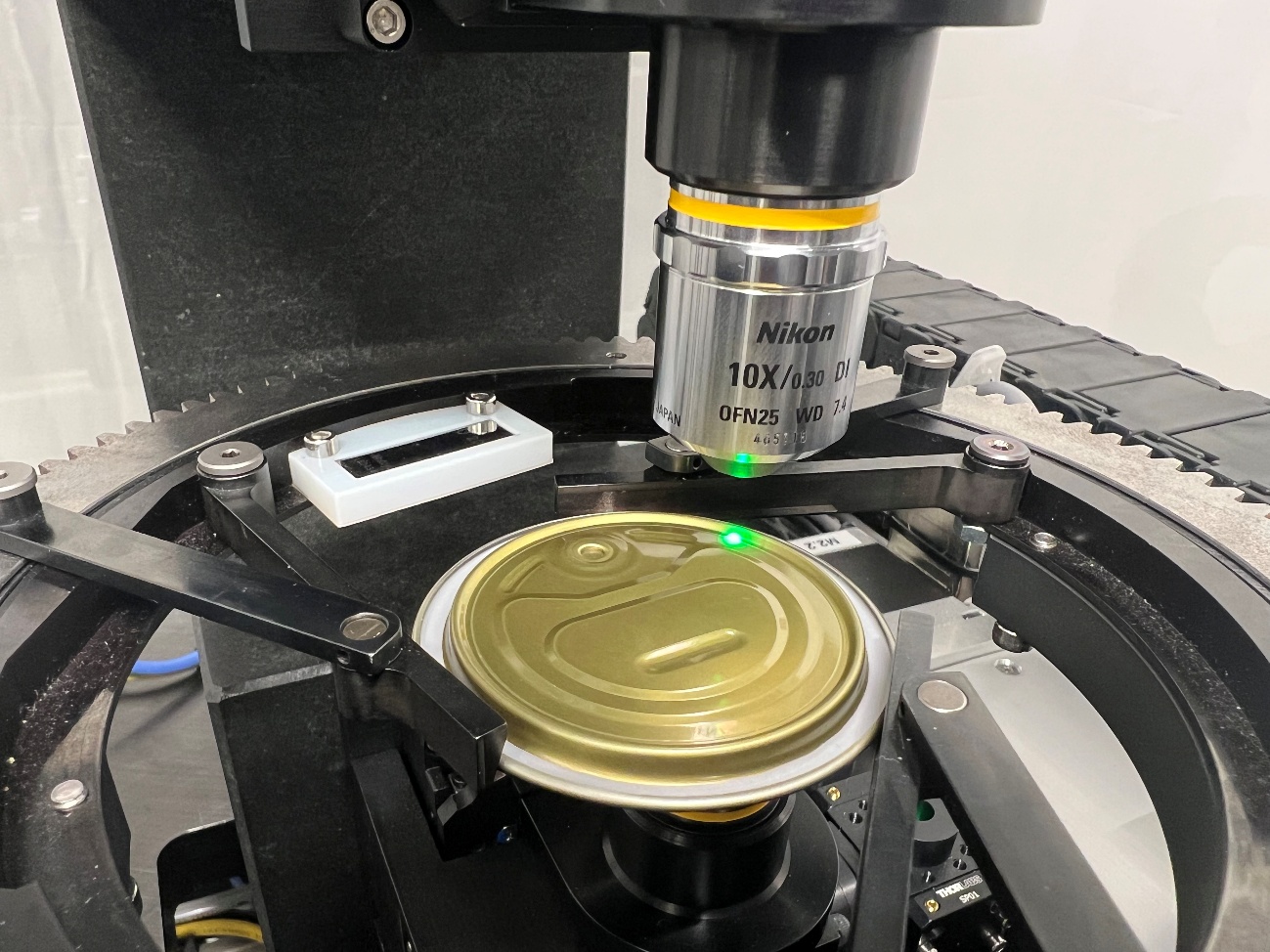

The other model presented by Physics, the Z345, allows for intelligent color control with X-Rite® technology

The Z345 model positions itself as one of the most advanced systems for automatic inspection of color and graphic elements on aluminum and steel beverage cans. Thanks to the integration with X-Rite® technology, this device performs detailed scans that allow comparing the decoration of cans with a master reference image.

The system can receive cans in any orientation, either directly from the production line or through an automatic feeder. A high-resolution camera “unrolls” the label for analysis and precisely aligns it with the Ci64 spectrophotometer, allowing for accurate evaluations at user-defined points. The entire process contributes to improving quality control, reducing manual intervention, and optimizing resources invested in inspection.

Innovation for a Sector in Transformation

Darren Hawkings, Sales Manager at Industrial Physics, highlighted that these developments represent a step forward towards sector automation:

“With the Z606 and Z345 models, we offer new tools to manufacturers looking to maintain high quality standards without compromising efficiency or resources. Our global research shows that the industry is ready to bet on innovation, and we are committed to supporting that evolution with reliable and precise technology.”