| TERM | MEANING |

| PAILS | High-capacity containers, characterized by having a lid with ato close the entire mouth of the container. It is fixed by means of a skirt divided into sectors that are folded over the flange of the mouth of the body. It is shaped like a bucket, hence its name. They are usually equipped with handles for handling. Its normal use is to contain paintings. |

| PALET

Palette |

Platform usually made of wood used as a base on which goods are arranged in an orderly fashion for transport or storage. On its sides it has some free spaces called “entrances” that are used to be taken by the “nails” or “horns” of the forklifts. |

| PALETTE

Pallet |

See pallet. |

| PALLETIZATION | Action of palletizing. It consists of placing the containers on a pallet inan orderly manner on different levels or floors for storage and transport. |

| PALLETIZER | Equipment or machine that performs the palletizing of the containers. |

| CENTRAL PANEL (COVER) |

Surface located in the middle of the lid. It is often flat and horizontal although sometimes it can be slightly concave or convex. Its anomalous deformation towards the outside can mean a bad state of the canning. It is usually used to print the codes and date of packaging by the filler. |

| SHEET PACK

Lump |

See bulge. |

| PARAFFIN

Wax |

Special sanitary wax used as a lubricant applied on tinplate.. The overlapping of the same can be done in solid state (rubbing bars of the same on the sheet) or liquid (spraying molten). |

| PARAFINADORA

Waxing machine |

Equipment that sprays a thin layer of molten wax on metal sheets and acts as a lubricant if the subsequent manufacturing process used is deep drawing.. It is used for example for sausage packagings. |

| BOWL WALL (CLOSING) |

Vertical surface of the trough on which the mandrel lip rests at the time ofclosing. It is a part of the lid. It is delimited between the wing radius and the wing radius wall of the tank. |

| GRILL (LITHOGRAPHED) Container |

See container. |

| EXCHANGE PARTS | Parts of a machine that change when the size (base or height) of the containeris modified. to manufacture. They must therefore be replaced by the appropriate ones for each case. |

| PASSIVATION (TINPLATE) | In tinplateThis name is given to the outermost layer of the same. It has a thickness of about 5 nm and is a contribution of chromium that is applied at the end of the manufacturing process. Minimizes the risk of oxidation and affects the adhesion of the varnishes and the solderability. |

| SKATING (CLOSING) |

Bulging in one area of the outer wall of the seal caused by incomplete formation of the seal due to slippage of theroller during thesecond operation.. Its origin may be in an insufficient pressure of the compression chuck, rollers or oil on the mandrel mandril. |

| PENETRATION (CLOSING) |

Ratio expressed in % between the length of the hook of the body and the height of the closure. |

| LOST

Espace |

See leakage |

| LOSS OF DRAFT

Loss of gluing |

Amount of metal – expressed in millimetres – used to perform the agrafadooperation.. This additional material must be added to the development theoretical development of the body of a agraphed container to calculate its development development. |

| LOSS OF GLUING

Loss of draft |

See loss of agrafado |

| LOSS OF OVERLAP

Loss of overlap |

Measurement expressed in millimetres (or other unit of length) of the overlapwidth.. It therefore evaluates the overlapping of the lateral edges of the body |

| LOSS OF OVERLAP

Loss of overlap |

See loss of overlap. |

| PROFILE | Geometric figure resulting from imaginary diametrically cutting the top or bottom.. It is configured by a series of gradients y expansion expansion This word is also used to define the outline of a locking roller. |

| DRILLING

Escape |

See leakage |

| FILM WEIGHT

Varnish load |

Amount of dry varnish (once cured) expressed in grs/m2 or in mgrs/in2 that a sheet of metal contains after application and baking. |

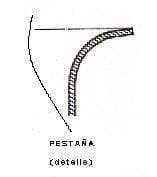

| TAB

Edge |

The flange that presents the body ( already formed) at each of its ends and that facilitates the closing operation (or union of the body with thecover).). It is made up of a flat part almost perpendicular to the wall of the body of the container and an arc that joins this flat part with the said body. |

| TAB CHAMPIÑÑONADA Chubby edge |

Tab defective. In it its flat part does not exist and the arc that joins it to the body extends to the outer edge of it. It can lead to a false closure. |

| DESIGNER

Edger |

Machine that realizes the flanges of the container. It can work by three systems: Rulina (rotating canister), buffer (fixed canister) or “spin”. |

| PICOS (CLOSING) |

Sealdefect characterized by “spikes” on the radius of the bottom hook (base of the seal).). It tends to show up mainly in the mounting and can be caused by excess compound or excessive pressure in the 2nd operation of closing operation. |

| PEAKS ON THE PANEL CENTRAL COVER |

Permanent deformations in the form of small outward ridges on the center panel of the lid. It is a defect caused by having exceeded its elastic limit. It is usually caused by an internal overpressure in the packaging during the process of sterilization process. |

| PIGMENTS (VARNISHES) |

Additives to be added to sanitary interior coatings to improve its characteristics. The most common are Al powder or OZn paste, their purpose in this case is to mask or absorb the sulphurization originating from certain protein-rich products. |

| PIN HOLE (HOJALATA) |

Perforation or very small hole that sometimes occurs as a manufacturing defect in tinplate.. Its presence is very dangerous because it generates leaks in the containers. |

| PISA BANDS (TROQUEL) Wake-up button |

In a die, the part that holds the strip firmly against the cutting blade during the die-cutting operation .. It is part of the punch (upper part of the tool). |

| PLATFORM

Pallet |

See pallet. |

| CLOSING PLATE

Closing mandrel |

See locking mandrel. |

| COMPRESSION PLATE | Closer part that receives, positions and holds the containerbody during the closing operation .. Moving in the direction of the axis of the containermoves the lid-body assembly lid-body assemblyhousing the lid in the chuck and providing a certain thrust (compression) during the cycle to maintain the body and the lid solidarity. Once this is finished, it descends, allowing the expulsion of the packaging. It is adjustable in position and force of compression. Its shape is a function of the packaging. The same as the chuckcan work by turning (for can empty) or fixed (full can).In the first case, the rotation can be produced either by the dragging of the mandrel (“crazy plate”) or by being linked to the seamer motor. seamer (“motorized chuck”) |

| POLYESTER (VARNISH) |

Very wide range of varnishes with properties sometimes quite different from each other depending on their formulation. |

| POLYMERIZED |

In the case of an organic coating or protective varnish of a container, this concept refers to the simple union of monomers that lead to a polymer of invariable centesimal composition through the action of heat by stoving the appliedvarnish . |

| POLYMERIZED

Curing |

See cured. |

| DUST ELECTROSTATIC |

Varnish in powder form to be applied on the inside of the electrically welded side seam of the body of a container to protect it from oxidation and chemical attack by the contents of the container.. It is applied by electrostatic deposition and subsequently requires the application of heat (baking) for its polymerization and adhesion on metal. It is generally white, although it can also be colorless or golden. |

| PORE | A hole in the metal of a container that results in a leak when filled with product, also referred to as small flaws of varnish or tin on the surface ofthe tinplate. |

| POROSITY (VARNISH) |

Presence of very small holes in the varnishedsurface of the sheet metal. It is measured by the number of pores per unit area. The higher it is, the better the quality of the varnishing is worse. |

| POROSITY (HOJALATA) |

This concept in tinplate indicates the existence of microscopic holes or discontinuities in its tinned surface. The porosity is inversely proportional to the tin coating. If it is excessive it is a very dangerous defect as it leaves steel exposed to corrosion as it is not protected by tin, |

| PUNCH HOLDER (TROQUEL) |

Punch clamping plate (upper part of the die) to the presscarriage. |

| PRICING (INDUSTRIAL PACKAGING) |

Metal or plastic membrane that placed in the opening or emptying area of an industrial container ( ring, gland, etc.) ensures the inviolability of the container. |

| PRESS | In the metalworking industry, this is the name given to any reciprocating motion machine that, by means of a complex die (or matrix) (generally cutting and drawing) , forms parts such as bottoms, deep-drawn containers, etc.etc. The mobile part (carriage) is driven by a crankshaft, which crankshaft, which transforms a rotation into a translation Presses are classified as follows: Manual, if the feeding of the raw material is done by hand and automatic, if the same is done by the press itself. Its working capacity (power) is measured in tons. |

| BURSTING PRESSURE | Inner pressure – normally expressed in Kgr/cm2 – at which a containercan be used for explodes. Very relevant and in some cases regulated data for containers that have to withstand high internal pressures such as aerosols. |

| STEP ONE (CLOSING) First operation |

See first operation. |

| FIRST OPERATION (CLOSING) |

Initial phase of the closure in which the cover curl is bent and crimped over the body flange by means of a roller, forming the hooks of the cover and the body. |

| TESTER

Tester |

Machine that checks for the presence of leaks in the containers.. They are available in various technologies: immersion in water, pressure, vacuum, light… |

| PROCESSOR

Autoclave |

See sterilizer. |

| PROCESS

Appertization |

See sterilized. |

| DEPTH OF CUBETA |

Height of the cell cavity or distance between the flange to the bottom of the cell wall radiusin the case of a lid. loose. If it is a packaging is the measurement from the top of the top of the closure to the bottom of the radius of the wall of the container . |

| PROPELLENT (AEROSOL) Propellant |

Pressurized gas containing an aerosol canister together with the active product. Allows to dispense the product in the form of fine droplets through the valve. |

| PROPULSOR (AEROSOL) Propellant |

See propellant. |

| PROJECTIONS OF WELDING |

Metal particles distributed on the inner surface of the body of a container generated during electric welding. of the same. Trigger metal exposure and are usually caused by an incorrect welding parameter or welding element (copper wire, sheaves, metal surface, temperature…) |

| PROJECTOR OF CLOSURES | Measuring equipment that allows to project on a screen the closure of a container at a very large scale and to evaluate its dimensions on the screen. |

| WELDING POINT | Each of the marks that linearly form the lateral electric weld of the body of a container.Each spot is generated by a half-pulse of the alternating electrical frequency used. |

| PUNCH | Male part of a tool ( or die)) that pierces or cuts a sheet by impacting on it. To do this, the blade is supported on another piece opposite to the first one (female) of identical size. The resulting element has the configuration of the female. This word is also used to designate the set of parts that form the upper part of a dieamong which is the punch itself. This assembly of parts has a reciprocating movement as it is fixed on the press carriagewhich travels the course of the race. race. |