| TERM | MEANING |

| BAND (TINPLATE) Strip |

See strip. |

| VARNISH

Enamel Organic coating nico |

They are organic coatings formed by dissolving a mixture of polymers (resins) capable of forming films, in a set of solvents with their corresponding additives. They provide the metal of the Thepackaging and the product the necessary protection against internal and external chemical phenomena (oxidation, corrosion…) They are usually applied flat on the metal intended for the manufacture of the product. can, although in some cases they can also be attached to finishedboat ((welding of thetwo-piece container) or to a part of it (welding of the side seam, lugs...). |

| WATER-BASED VARNISH | Family of varnishes that use water as the main solvent. They are less polluting than the solvent-based ones, although their application is more complex. |

| FINISHING VARNISH | The last coat of varnish is applied on the exterior lithography – on metal – to protect it from physical attacks – rubbing, scratches, heat, etc. – and chemical attacks – packaged product, humidity, etc. -. |

| COUPLING VARNISH Armhole | See armhole |

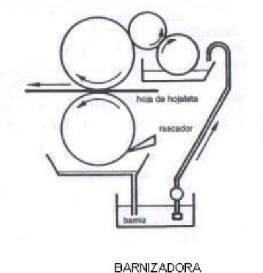

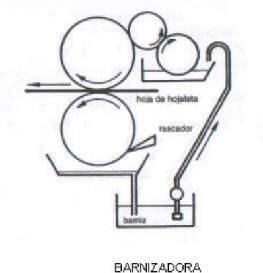

| VARNISHING Lacquering | Operation of applying varnish on metal in a varnishing machine. |

| VARNISHING MACHINE | Machine that applies varnish on the metal sheets prior to the manufacture of the packaging components. This is done by passing the sheets through a pair of rollers, one of which is impregnated with varnish. |

| VARNISHING MACHINE CHAINS |

A varnishing machine characterised by the fact that it aligns and moves the metal sheet by means of chains fitted with fingers that push the metal sheet along its rear edge in its forward direction. It is not very accurate. |

| VARNISHING MACHINE CLIPPERS |

Varnishing machine characterised by the fact that it aligns and moves the metal sheet by means of two grippers that hold it by the front edge of the sheet in its direction of advance. It is highly accurate. |

| BARS | Defect that can occur in the varnishing operation. Longitudinal and parallel areas (resembling “bars”) of a different shade than normal appear. |

| DIE BASE (DIE) Strain Sufridera |

Part by means of which the lower part of a dieis fixed to the press table . It serves as a support for the set of parts that form the lower part of the die. |

| BASIS OF CLOSURE (CLOSING) |

Lower part of the lock. It is the thinnest part of it, |

| BIN | Large capacity metal containers, at least 25 litres and upwards. |

| BIGORNIA | In a shrink-wrapping machine, this is the name given to the tool (mounted on the machine) that acts as an anvil on which the flat body of the container is formed to give it the appropriate format. |

| COUCHÉ WHITE (VARNISH) Lacquer White enamel |

White exterior varnish that is applied as a base – first pass – in a lithography process. It improves the adhesion of the inks on the metal as well as performing the function of the white colour in a four-colour process. |

| COIL (METAL) |

Rolled metal coil(tinplate, aluminium, etc.) and ready to be used as it can be delivered by the steel industry to packaging manufacturers. Its weight usually varies between 5 to 12 tons. |

| BODYMAKER (PACKS 2 P.) Bodymaker (packs 2 p.) |

See forming machine (2 piece packaging). |

| BODYMAKER (3 PIECES PACKAGING) Forming machine Grappling machine |

See trainer. |

| EDGE

Tab |

View tab |

| EDGE CHUBBY Chubby tab |

Seechubby eyelash |

| SHARP EDGE (CLOSING) |

Defect in the closure. The summit of the same instead of being rounded, appears flattened horizontally forming an inward projection. It is usually caused by working with a worn chuck or by the 2nd operation ruins being too tight. May result in metal breakage. |

| CURL EDGE | Cutting edge of the curl end of the loose cap (before closing). It is not protected by tin and therefore has visible steel that can cause oxidation. |

| EDGING MACHINE

Clipping machine |

See eyelasher. |

| BORDERING MACHINE

BORDONER Nerving machine |

See cordoning machine. |

| LACES

Laces Ribs |

See laces |

| EJECTOR (DIE CUT) Ejector Ejector |

See ejector. |

| WASTE PUNCH (DIE CUTTER) Band Press |

See bandeau. |

| CAN

Can Metal container |

See can. |

| BUTTON (EASY OPEN LID) |

Protrusion made on the panel of the easy-open cover, used to fix the ring on it by means of the rivetingoperation. |

| BOX-BANDE (PACKAGING) |

Predecessor type of easy-open packaging. It consists of four pieces: normalbackground, body with the upper part with a diameter reduction and straight finish, lid with a skirt that fits externally into the reduced mouth of the body and metallic strip that is welded in all the peripheral junction area of the lid with the body and that acts as a link between the two. Opens by pulling on the end of the strap |

| WELDING ARM (WELDER ELECTRIC) |

Metallic bar of variable section and approximately circular that is fixed at one end to the welding machine, leaving the other end free to support the welding wheel. Through this arm pass different pipes (varnish, nitrogen…) necessary in the welding area and the copper wire used as electrode. The bodies to be welded are fed along this arm, embracing it inside. This arm is a function of the container diameter to be welded and is therefore sometimes a part of the machine to be changed when changing the container diameter. |

| BRUÑIDOR | Tool consisting of a roller usually made of high hardness steel with a handle, which is used to improve the cutting of a low hardness punch when the cutting edge is dull. Its use requires some manual dexterity. |

| LEAF BULK

Package Bale |

A stack of ordered and packaged sheets of metal, obtained on a tinplate or other sheet metal fabrication line (or on a coil slitter ). It is usually adequately protected for external or internal transport. This is also the name given to the stacks or bundles of sheets being produced in the lithography or cuttersections. |