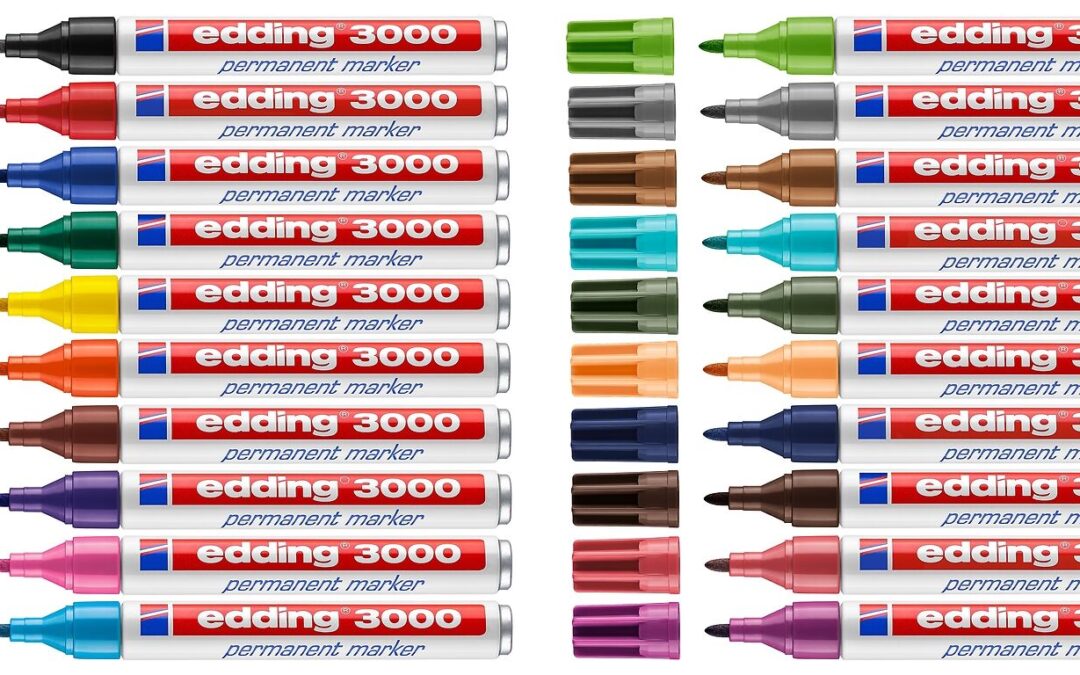

In a world where environmental awareness is becoming a priority, edding, together with its partner LINHARDT Group, is taking a significant step towards sustainability with the transition of the production process of its edding 3000 markers to post-consumer recycled (PCR) aluminum.

“Small steps, big impact!” is the motto guiding this journey towards ecological and social sustainability. By using PCR aluminum instead of new aluminum, edding and LINHARDT Group are taking a vital step towards reducing CO2e emissions. According to estimates, this transition saves approximately 92% of CO2e emissions in the production of the marker barrel.

However, this achievement did not come without challenges. Extensive research and careful development was required to find the right material to meet edding’s quality standards. Aluminum marker housings have incredibly thin walls, which presents unique difficulties in the production process.

After two years of hard work, edding and the LINHARDT Group have succeeded in creating the necessary conditions for this important change. By using PCR aluminum from high-voltage cables and old printing plates, they can now guarantee high material purity and maintain the quality of the final product.

“We are excited about this progress and look forward to continuing to find innovative solutions for a more sustainable world.” commented an edding representative. “We thank everyone who is part of this journey towards a greener future.”

With this initiative, edding demonstrates its commitment to sustainability and its ability to lead the change towards more responsible practices in the industry.