Introduction

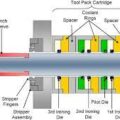

In the can making industry, the quality of the final product is heavily dependent on the precision and efficiency of the manufacturing process. One of the critical components that contribute to this process is the tool pack, which houses various parts responsible for shaping and forming the can. Among these components, contoured pins play a vital role in controlling die movement and ensuring the production of high-quality cans. This article delves into the function, design, and benefits of contoured pins in the modern can making tool pack.

Contoured Pins: Function and Design

The original and oldest Pride Floating Tool Pack model utilizes steel coil springs and steel pins to control die movement within the die modules. However, the modern design has evolved to incorporate rubber springs and contoured pins, which are custom ground to the can maker’s die size. These contoured pins work in conjunction with rubber springs to effectively control die movement and dampen vibrations coming from the ram as it passes through the tool pack.

The contoured pins are designed to have a precise fit with the die size, ensuring that the die moves smoothly and accurately within the die module. This precision in movement is crucial in preventing any unwanted marks or deformations on the thin wall portion of the can during the manufacturing process.

Benefits of Contoured Pins

Vibration Dampening: The use of contoured pins in conjunction with rubber springs helps to absorb vibrations generated during the can making process. This dampening effect reduces the risk of marking or ribbing on the thin wall portion of the can, resulting in a better, brighter final product.

Improved Die Movement Control: Contoured pins provide a more accurate fit with the die size, allowing for precise control of die movement within the die module. This precision ensures that the die returns to its center position before the next approach of the punch, contributing to a smoother and more efficient manufacturing process.

Vacuum Breakage: In the can making process, a vacuum can form between the die and the surface behind it due to the pressure exerted during die movement. Contoured pins, in combination with air grooves in the module, help break this vacuum and allow the springs and suspension pins to return the die to its center position. This ensures that the tool pack works optimally and contributes to a higher quality final product.

Conclusion

Contoured pins are an essential component in the modern can making tool pack, providing numerous benefits in terms of vibration dampening, die movement control, and vacuum breakage. By incorporating contoured pins into the tool pack design, can makers can ensure a more efficient manufacturing process and produce higher quality cans that meet the demands of today’s consumers.