Bunting has developed three designs of Permanent Cross Belt (PCB) Magneto Overband, with different magnetic polarities, to suit an increasing range of applications. Magneto Overband Magnetos are mounted on conveyor belts to separate ferrous metal from non-magnetic material and are commonly used in industries such as mining, stone quarrying, recycling and timber.

The magnetic field of a Permanent Crossbelt Overband Magnet (PCB) is generated by loading blocks of ferrite or rare earth magnets mounted inside a stainless steel box with a steel bar at the back.

The steel bar forces the magnetic field to propagate through and out of the bottom of the magnet box, which is directed onto a conveyor belt carrying bulk materials such as aggregate or scrap.

Although all three designs operate on this basic principle, that is where the similarities end.

The magnetic field of the three designs of Permanent Cross Band (PCB) Overband Magnets is defined as ‘Single Pole’, ‘Double Pole’ or ‘Triple Pole’.

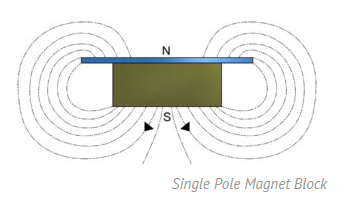

Single Pole Overband Magnets

The Single Pole design (Single Pole PCB) is the simplest and most common design of Permanent Crossband Magnet Overband (PCB). Constructed with a single magnetic block and a steel bar at the back, the north pole is located on the back bar with the south pole at the bottom of the block. The field moves vertically, from north to south, projecting from the south pole towards the material conveyed on the conveyor belt.

Single Pole Magnet Block

The Single Pole design eliminates general scrap metal from a range of products in a variety of applications. This design offers a reliable and cost-effective solution for quarries, mobile recycling plants and recycling operations.

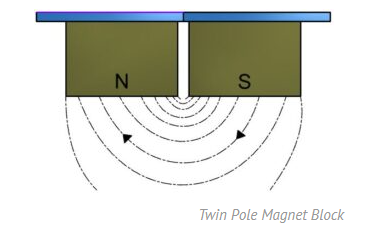

Double Pole Overband Magnets

A Double Pole configuration uses two separate magnetic boxes, mounted side by side on a single steel bar, each with a different magnetic pole. The magnetic field flows from south to north (from one box to the other), producing a deep magnetic field that projects outward and downward from the faces of the magnet.

Double Pole Magnet Block

The improved separation performance of the Dual Pole PCB allows smaller ferrous particles to be captured. The dual pole configuration has the advantage of lifting long, thin ferrous metal, typically steel rod, in a flat orientation which facilitates discharge and reduces belt wear. This Double Pole feature occurs because the different poles of the two magnetic boxes attract opposite ends of the ferrous metal, forcing it to lie flat in the field. The Single Pole design attracts one end, resulting in one end striking the tape or the face of the magnet box.

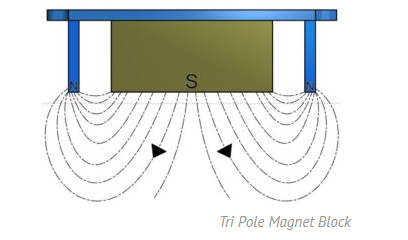

Triple Pole Magneto Overband

The Permanent Crossband (PCB) Triple Pole Overband Magnet (PCB Tri-Pole) has two additional steel side poles mounted on either side, with a gap, of a single central magnetic box. Each of the side poles has a north magnetic pole, with the center of the box being the south pole (i.e., three poles). This generates two magnetic fields running from the box to the steel side poles. The side poles reduce flux leakage and concentrate the magnetic field downward toward the product.

Triple Pole Magnet Block

The greater depth of the magnetic field generated by the Tri-Pole PCB results in a higher suspension height of the Magneto Overband, which is ideal for deeper troughed conveyors and higher material loads. The Tri-Pole model captures smaller ferrous metals that are difficult to separate with a Single Pole PCB.

An additional advantage is that the shape and direction of the magnetic field limits any magnetization of the Magneto Overband frame, which is ideal when processing materials such as scrap wood containing nails and screws.

Selection of the Permanent Cross Band Magnet Overband (PCB)

Selecting the correct Permanent Crossband Magnet Overband (PCB) is dictated by the application. Bunting’s application engineers evaluate the ferrous metal separation target (i.e., plant being protected or metal being recovered); the nature of the ferrous metal (i.e., shape, size, etc.); and the material being conveyed (i.e., size range, depth of charge). These criteria help the team select the optimum PCB for any given application.

With decades of experience in the design and construction of permanent and electro overband magnets, Bunting continues to provide innovative and many customized solutions in magnetic separation.