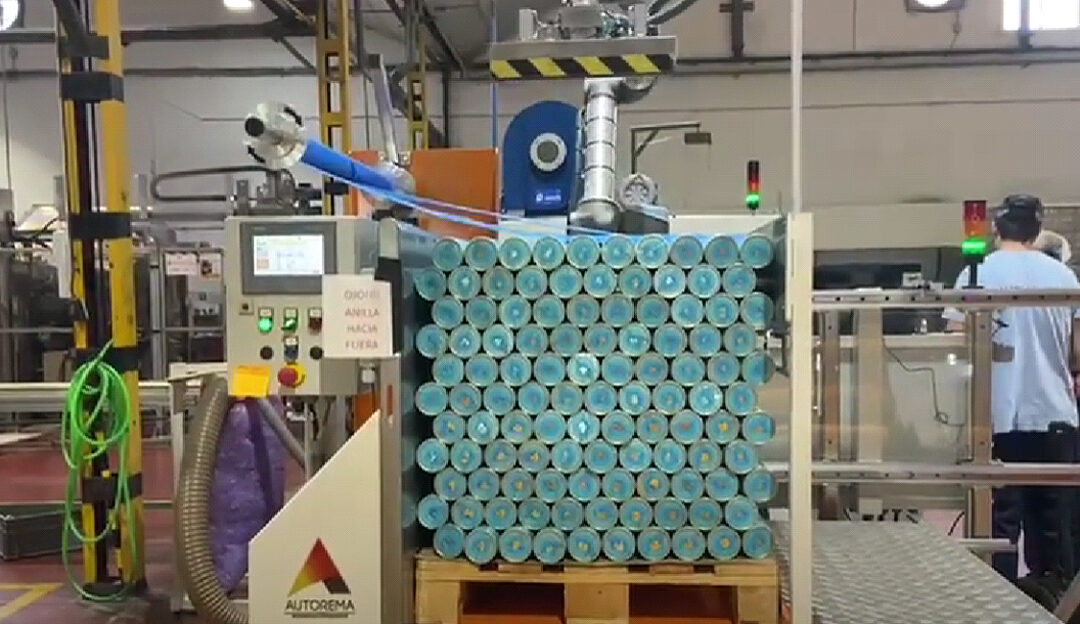

The engineering company Autorema has introduced the so-called Industry 4.0 in factories producing metal packaging, as well as in canning companies, through the incorporation of collaborative robots. These types of robots do not require extra security such as perimeter fencing and security scanners.

Autorema’s managers add that this new Industry 4.0 technology is designed to work in coexistence with people, they are completely safe in the interaction with workers, something that adds an extra peace of mind. The machine stops if you touch it, says Autorema. Moreover, they add, we are the only ones who have managed to incorporate this type of technology within the metallographic industry.

Industry 4.0 combines advanced production and operations techniques with smart technologies that will be integrated into organizations, people and assets.

This revolution is marked by the emergence of new technologies such as collaborative robotics, analytics, artificial intelligence, cognitive technologies, nanotechnology and the Internet of Things, among others.

is driven by the continuous and cyclical flow of information and actions between the physical and digital worlds. This flow takes place through a series of iterative steps known as physical-to-digital-to-physical (PDP).