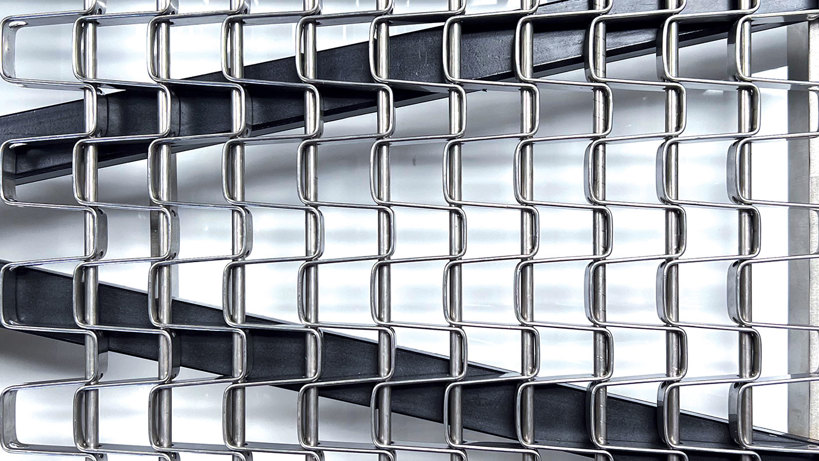

Ashworth has introduced an innovative solution for premature wear in can washing systems (can washers), a common problem caused by constant contact between metal belts and metal beds. The company’s proposal: install a plastic bed liner that eliminates metal-to-metal friction and significantly extends the lifespan of conveyor belts.

Made with high-strength engineering plastics—the same ones Ashworth uses in its plastic retention mats for washing systems—these liners offer exceptional resistance to chemicals, high temperatures, wear, and mechanical damage.

According to Ashworth, using metal belts combined with plastic liners not only represents a more economical alternative to using full plastic belts but also improves the can washing process. Among the highlighted advantages are reduced chemical carryover, greater durability, less maintenance requirements, and compatibility with standard sprockets available in the market.

Furthermore, this solution allows companies to avoid the costly and labor-intensive replacement of metal beds, reducing downtime and operational expenses.

The immediate availability of materials and ease of installation make Ashworth’s liners an increasingly adopted option in the industry, especially by manufacturers looking to increase the efficiency of their operations without compromising washing quality or system durability.