Introduction

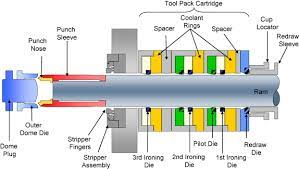

Die Modules are essential components of a tool pack system, often used in the manufacturing and metalworking industries. These modules play a crucial role in shaping and forming various materials into desired shapes and sizes. In this article, we will explore the various aspects of Die Modules, including their construction, maintenance, and proper installation procedures.

Construction and design

Die Modules are designed to house Dies, which are the actual shaping tools used in the manufacturing process. These modules are typically made of durable materials like steel, ensuring they can withstand the pressure and force exerted during the shaping process. The Dies themselves can vary in size, shape, and material, depending on the specific application.

Maintenance and inspection

egular maintenance and inspection of Die Modules are essential for ensuring their longevity and optimal performance. Some key aspects of maintenance include:

Inspecting Tool Pack parts for burrs, nicks, dents, and other damages. Any raised damage should be smoothed using a stone. Any raised damage should be smoothed using a stone.

Removing and inspecting the internal area of the Tool Pack where the Die was removed. Damaged or rough surfaces inside the Tool Pack Modules should be stoned and cleaned up.

Ensuring the new Die is free of nicks, dents, burrs, or any other rough surface conditions. Dies that are not in good condition should be repaired or replaced.

Installation and adjustment

Proper installation and adjustment of Dies within the Die Modules are crucial for achieving the desired results in the manufacturing process. Here are the steps for correct installation:

Ensure the Die fits smoothly into the centering pins and goes into the Module without difficulty. It should not be too loose or too tight.

For Die Modules with cover plates, install the cover and tighten the screws evenly. Reach inside the Die and ensure it can move off-center (float). If the Die is too thick or has too much clearance, change the springs or contact your dealer for instructions.

For Die Modules without cover plates, use a straight edge to ensure the Die is below the open face of the Module. Follow the same instructions for checking the float of the Die.

Replacing the redraw Die should be done in the same manner, but without any built-in float. The fit must be smooth and close, without requiring force or hammering to install.

Double-check that the Dies are installed correctly, facing the right direction, and in the proper order.

Stone the wear plates and mounting rails in the Cradle, ensuring a smooth and burr-free surface. Clean out the Cradle and carefully install the Tool Pack Modules.

Conclusion

Die Modules are critical components of a tool pack system, playing a vital role in shaping and forming materials. Proper maintenance, inspection, and installation procedures are essential for ensuring the longevity and optimal performance of these modules. By following the guidelines outlined in this article, you can ensure your Die Modules continue to function efficiently and effectively in your manufacturing processes.