| TERM | MEANING |

| EXIT

Escape |

See leakage. |

| PRIMARY SCROLL | Operation of “zig-zag” cutting of a coil into sheets. It is used when the metal is intended for round bottoms or deep-drawn bodies . The resulting sheets have two straight sides – corresponding to the width of the coil – and two “zig-zig” sides – coinciding with the cut. This operation is performed on a coil slitting line. |

| SECONDARY SCROLL | Zig-zag cutting of a sheet into strips, which in turn has been previously cut into primary scrolls.. It is used when the destination of the strips is for round bottoms o deep-drawn bodies. The strips The resulting strips have their four sides in a “zig-zag” shape. |

| DRYING

Curing |

See baking. |

| SECOND OPERATION (CLOSING) Second step |

Final closing phase in which the hooks formed during the first operation are tightened and pressed by means of a roller The compound deposited on the flange of the lid occupies the free spaces to obtain an airtightseal. |

| SECOND STEP (CLOSING) Second operation |

See second operation. |

| SEMICONSEVA | Food canning that does not require a heat sterilization process. The product is packaged and ready for distribution. A typical case is “anchovies in oil”. It requires low temperature preservation and its life is shorter than conventional preserves. |

| SEPARATORS

Interposers |

Cartons to be placed between each floor or level of containers contained in a full pallet. It is therefore an element of the packaging commonly used for empty containers and their measurements practically coincide with those of the wooden pallet that serves as a base for the system. |

| SIMPLE REDUCED (HOJALATA) |

Tinplate classic. Your base steel has been obtained in a single cold rolling or cold thinning process. |

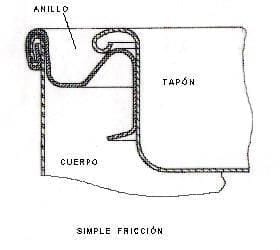

| SIMPLE FRICTION (FRICTION LOCK) |

Closure form between the cap and the rim of a container for industrial products (paints, etc.) whereby there is only one adjustment surface. That is to say the plug grips on the ring by means of a single wall. |

| SISA (VARNISH) Coupling varnish |

A varnish – usually colourless – that is applied to the outside of metal to serve as a base for others applied to it or for printing inks. Its objective is to improve the adhesion of the set – or system – of inks and varnishes on the tinplate. |

| OUTSIDE SYSTEM | A set of varnishes applied to the outside of a container to protect it and its lithography.. It is generally made up of a white enamel plus a finishing varnish. |

| INTERNAL SYSTEM | Set of varnishes of complementary characteristics that are applied sequentially on the inside of a container for its protection. |

| SITA | Tinplate unit of measure per surface, equal to 100 square meters (System Internacioinal Timplate Area). Equivalent to 4,943 base boxes or to 5,537 European base cases. |

| OVERLAY | Piece generally made of plastic that fits over the closure of a full container with aneasy-to-open lid, which can be used as a lid once it has been opened, allowing better preservation of the product when it is consumed on successive occasions. |

| FLAP | Overlapping or overlapping part at both ends of the agrafada side seam of the body of a container.. In this area there is only one double thickness of material instead of the four as in the rest of the sewing, thus facilitating the realization of the closing. |

| OVERLAY

Solape |

Overlapping of an edge of the body development on the other. It allows the electric welding between the two and gives rise to the welded side seam. |

| SOLAPE

Overlapping |

See overlapping. |

| SOLDABILITY | Property of being able to be welded certain materials. For example, tin is said to have high solderability, because it solders easily. |

| WELDING MACHINE

Counter welding machine |

Machine that performs the welding of the side seam of the container body.. It can be of the type electric soldering by spot soldering or by the addition of a molten tin-lead alloy. |

| ELECTRIC WELDING | Technique of joining parts. It consists of passing an alternating electric current of low voltage and high intensity and frequency through the parts to be joined by means of electrodes until a certain fusion is achieved due to the heat generated (Joule effect). In the metalworking industry, it is one of the ways to make the side seam of the body among other applications. |

| ELECTRIC WELDING HOT |

Electric welding in which the metal has exceeded the proper temperature and is brittle and fragile. |

| ELECTRIC WELDING FRIA |

Electric welding in which the metal has not reached the right temperature. Peels off easily. |

| SIDE WELDING | The side seam is held in place by welding the overlapof the body. This welding can be done either by heat (electric) or by the addition of a molten metal alloy and is called side welding. |

| SHADE (TROQUEL) |

Hat-shaped piece (cap) that finishes off the top of a die.. It is mounted on an elastic system (spring), it receives the impact of the extractor from the press at the top of the carriage stroke carriage. As it is solidly linked to the ejector from punch ejectorPull the workpiece out of the punch. |

| SPRINGBACK ANGLE (HOJALATA) |

Quick test to determine the yield strength of a tin plate. It has its main application in tinplates type double reduced because due to their thinness it is not reliable to determine their hardness and hardness. hardness by the conventional procedure (use of the durometer). It consists of subjecting a test tube to the tinplate to be tested, of certain dimensions, to a bending – on a special tool – and to measure on a template the angle of the same once it has been released from the bending force. Known this angle and the thickness of the tinplate is carried on a double-entry graph – nomogram – and gives us its elastic limit. This test gives approximate but valid values for a simple and quick determination of the limit of altitude without the need for the laboratory equipment necessary for its determination which is quite expensive. |

| SUFFER

Matrix Base |

See matrix base |

| SULFURATION | Chemical phenomenon caused by the attack to the tin of the inner wall of the container by the sulphur ion formed as a consequence of the degradation of the proteins – of the contained food – by the action of the heat of the autoclave. It usually manifests itself in blackish spots. |