Description

Impact of sealant application and lid geometry on double seam quality

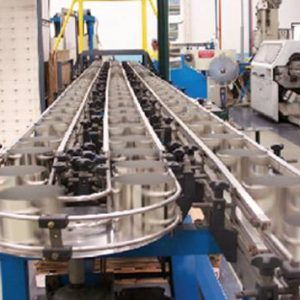

This technical course delves into the relationship between sealant application, lid geometry, and the formation of a secure, high-quality double seam. It analyzes the critical factors that influence hermeticity, product protection, and defect reduction during the seaming process.

The main sealant variables—such as viscosity, applied quantity, and uniformity—are reviewed, along with the dimensions and geometric tolerances of the lids (height, profile, angles), and how their interaction impacts seam consistency.

In addition, practical guidelines are offered for diagnosing common failures, optimizing online application, and establishing quality controls that guarantee food safety and minimize claims.

Featured content:

-

Key sealant parameters: types, viscosity, quantity, and application.

-

Influence of lid geometry on seam formation.

-

Common defects in the double seam and their causes.

-

Quality control and verification methods in the plant.

-

Good practices for optimizing container hermeticity and safety.

-

Examples of real failures and corrective measures.

Aimed at:

Quality managers, maintenance technicians, production supervisors, process engineers, and lid manufacturers seeking to ensure the consistency and reliability of the double seam.

Methodology: The course combines theoretical sessions with practical examples and real case studies, facilitating the direct application of acquired knowledge in the industry.

Duration and modality: The course lasts 3 hours and is offered online, allowing access from any location.

Language: English, Spanish and Portuguese

Certification: Upon completion of the course, participants will receive a certificate of achievement that accredits the knowledge acquired in sealants, lid geometry, and their impact on the quality of the double seam.

Reviews

There are no reviews yet.