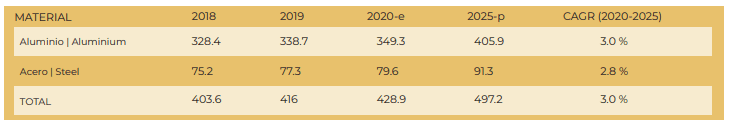

Food and Beverage Metal Cans Market by MATERIAL

Key results

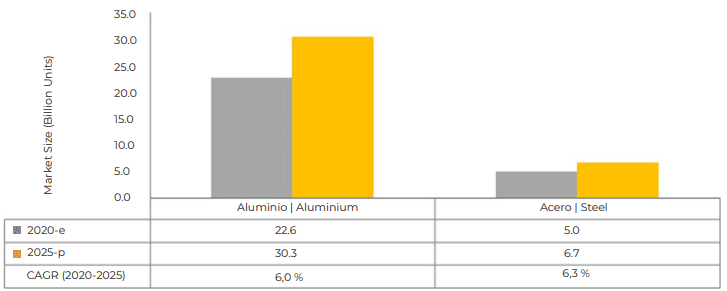

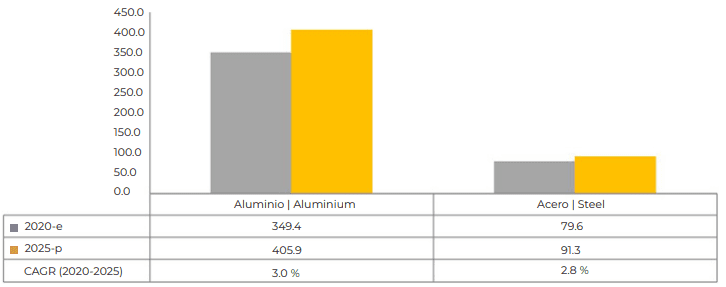

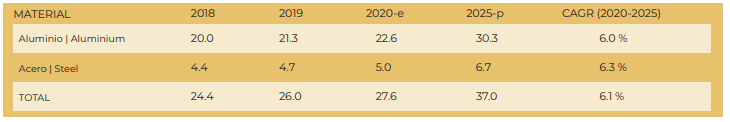

– The aluminum segment is estimated to dominate the food & beverage metal cans market with a major share of around 82.4% in 2019, by volume. It is projected to reach 405.9 billion units by 2025.

– High aluminum recycling rates and growing concern for sustainable packaging support the growth of aluminum in the metal can market.

– The steel segment is projected to grow at a higher compound annual growth rate of 6.3%, in value, during the forecast period due to rising steel raw material prices.

Introduction

This study considers the most commonly used materials, such as aluminium and steel, for the metallic packaging of food and beverages. With the growing demand for food and beverage products and ever-changing consumer preferences, the packaging industry is evolving, leading to the development of innovative, environmentally friendly, sustainable and cost-effective manufacturing processes. In the food industry, steel is widely used for packaging various types of food, such as cut fruits and vegetables and processed foods.

According to the Canadian Association of Recycling Industries (CARI), 63% of aluminum cans are recycled annually. However, aluminium finds wide applications in the beverage industry. In addition, according to the Bureau of International Recycling (BIR), 1.6 million people work for the recycling industry. About 45% of the world’s annual steel production, 40% of the world’s copper production and 33% of the world’s aluminium are produced from recycled material.

FOOD & BEVERAGE METAL CANS MARKET SIZE, BY MATERIAL, 2020 VS. 2025 (USD BILLION)

FOOD & BEVERAGE METAL CANS MARKET SIZE, BY MATERIAL, 2020 VS. 2025 (BILLION UNITS)

FOOD & BEVERAGE METAL CANS MARKET SIZE, BY MATERIAL, 2018-2025 (USD BILLION)

FOOD & BEVERAGE METAL CANS MARKET SIZE, BY MATERIAL, 2018-2025 (USD BILLION)

Due to the various advantages of aluminium (high thermal conductivity and lower consumption during the recycling process) over steel, the aluminium segment dominates the market of

metal cans for food and beverages, by material.

Aluminium cans

100% RECYCLED ALUMINUM CLABLE RATES MAKE IT SUITABLE FOR THE BEVERAGE INDUSTRY.

Aluminium is a very ductile material. It is derived from bauxite ore. It is the most preferred raw material and is used for packaging processed food and beverage products. Its low weight, impermeability and high flexibility make it a perfect material for packaging. Aluminium has wide applications in the beverage industry. It reduces the cost of transportation and works as an excellent barrier against air, light and microorganisms. It can be moulded into an infinite number of shapes. Aluminium is 100% recyclable and contains 35% recycled content. It can tolerate temperatures ranging from 40 degrees Celsius to 350 degrees Celsius. Aluminium cans have a better carbon footprint compared to other packaging materials used in the food and beverage industry.

Aluminum is a very cost effective raw material used in the food and beverage industry and can customize packaging with colors, 3D printing and embossing. Therefore, technological advances have led manufacturers to reshape their strategies by using various sizes of cans, along with different shapes. Aluminum cans are convenient to store in the refrigerator and in the oven. Recent years have seen changes in consumer preferences for food and beverage packaging. According to the U.S. Environmental Protection Agency (EPA), 1.9 million tons of aluminum beer and soda cans were generated, and 49.2 percent of aluminum beverage cans were recycled. Therefore, aluminium cans are estimated to dominate beverage applications but have limited use in the processed food industry.

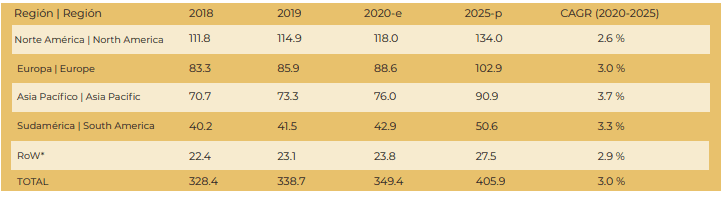

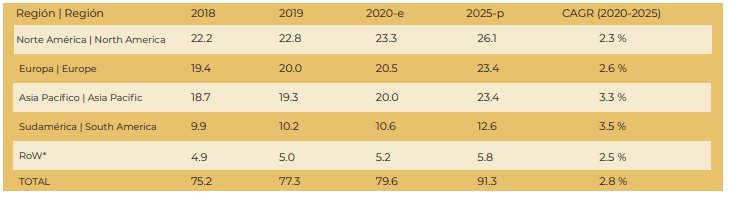

ALUMINUM CANS MARKET SIZE, BY REGION, 2018-2025 (USD BILLION)

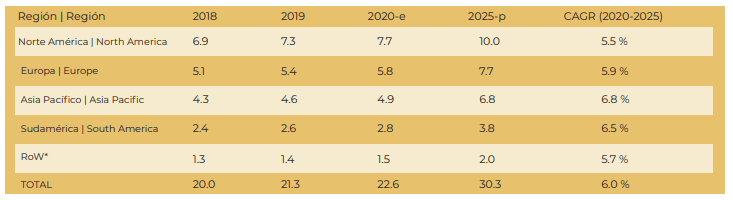

ALUMINUM CANS MARKET SIZE, BY REGION, 2018-2025 (BILLION UNITS)

Due to high consumption of carbonated beverages in North America, the region dominated the market, by material, in 2018.

Moreover, high usage of aluminum as raw material in the manufacturing of cans helps to drive the aluminum market.

Steel cans

ALUMINUM PROFITS LOWERING SALES OF STEEL CANS

Steel is one of the preferred metals used for the manufacture of metal cans, followed by aluminum. There are two main types of steel grades used for food packaging applications. Electrolytic tinplate (ETP) and electrolytic chromium coated steel (ECCS). Generally, steel cans are used to store food products. Previously, steel and tin were used for the manufacture of cans, but gradually, with the use of aluminum cans in the market, steel began to lose its share in the beverage industry. Therefore, the benefits of aluminum as a raw material reduced the sale of food cans. Tin is used as an internal coating in the manufacture of steel cans to prevent corrosion caused by the reaction of the internal contents. It also prevents oxidation. The internal tin coating helps to protect the taste of food products. Steel cans are mainly used to preserve processed foods, seafood, dairy products, syrups, and bakery and confectionery products. Steel therefore represents the smallest share of the beverage market.

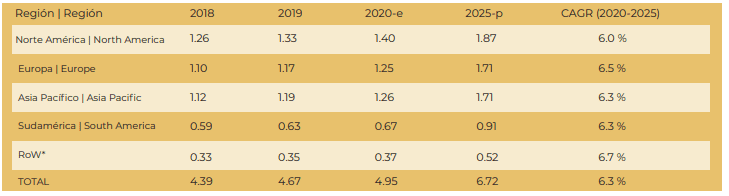

STEEL CANS MARKET SIZE, BY REGION, 2018-2025 (USD BILLION)

STEEL CANS MARKET SIZE, BY REGION, 2018-2025 (BILLION UNITS)

The growing trend of consuming canned foods and ready-to-go meals in developed regions, such as North America, makes it a dominant region in 2018

in the steel can market.

0 Comments