Soudronic launches PowerCoat for a flawless and safe finish on metal containers

Soudronic has just launched a very interesting new product to keep cans in perfect condition, specially designed for those manufacturers who are not satisfied with the visible weld seam of their metal cans: it is PowerCOAT.

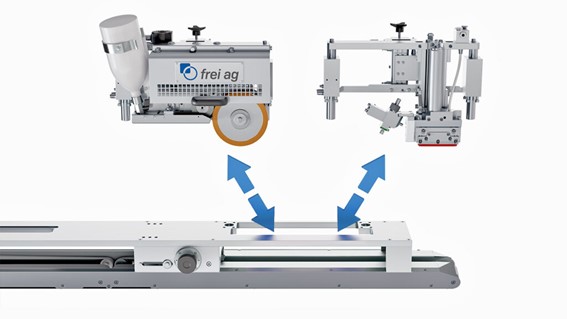

It is enough to choose the new color of the powder type that perfectly matches the decoration of the can body. PowerCOAT makes it possible to change the color of powder, normally a time-consuming process, within 15 to 30 minutes. The application thickness of the highly opaque powder is precise and constantly monitored. In addition, the easy interchangeability of applicators allows quick switching between lacquer and powder coating.

Soudronic powder systems are well known as the only systems that achieve high processing speeds of up to 100 m/min. In this case, the application is performed in a precise and controlled manner.

To ensure that only a minimal amount of powder enters the can, they have developed a system that constantly monitors and adjusts the spacing between each can body.

In addition, the ZeroGAP air conveyor allows a quick changeover from lacquer to powder coating and vice versa.

In addition, Soudronic’s basic dashboards ensure that this process is carried out in a controlled and accurate manner, with live production statistics at line, machine and component level:

- Line/machine status

- Efficiency

- Top 5 error statistics

- Production counter

- Event registration