Choosing the right packaging: pros and cons of 2pc vs. 3pc cans

Food manufacturers still have a dilemma about what type of can to use for packaging their products. On the one hand, traditional three-piece cans have been around for centuries and are easy to produce. But on the other hand, there are innovative packages composed of only two parts that offer significant advantages in terms of production and raw material consumption. What is the best alternative then?

The 3-part containers consist of a can manufactured with a sewn shell with one end and an attached lid. These have several benefits, such as good strength, ease of size scalability, and versatility to contain different materials. On the other hand, there are some disadvantages that include the higher material expense on the sides and top due to the seams, as well as being vulnerable to potential weak points.

Considering the two-piece can has its own advantages, such as good packaging that protects products in an optimal way, as well as being highly productive with lower raw material costs. In addition, it can be produced quickly.

But where do 2-piece and 3-piece cans work best?

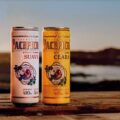

2-piece cans dominate the beverage industry, thanks to their excellent sealing properties and the fact that the manufacturing process is particularly suited to lightweight aluminum and alloys. These materials have the added advantage of helping beverages cool quickly.

The 3-piece design is very popular in the industrial sector, as it is feasible to assemble without the need for expensive tools and machinery. Additionally, this kind of cans offers a great number of possibilities for opening and closing, thus achieving greater convenience, simplicity and versatility in the manufacturing process.

On the production side, 2-piece cans require advanced technologies and precise measurements to create an optimal package, but all can production lines benefit greatly from a good quality control testing regime. The can can is a multi-layer system that allows you to measure and test cans before and after production to ensure their integrity.

Although a specialized system is needed to fully test each type of can, there is a lot of test equipment that is common to both, including double seam and implosion testing.

Both 3-piece and 2-piece aluminum may have become integral to the success of many different industries. Cans are used by companies working in everything from food and beverage to the paint and automotive sectors. They have helped millions of people to eat fresher produce and millions of companies to transport their products safely… all over the world.