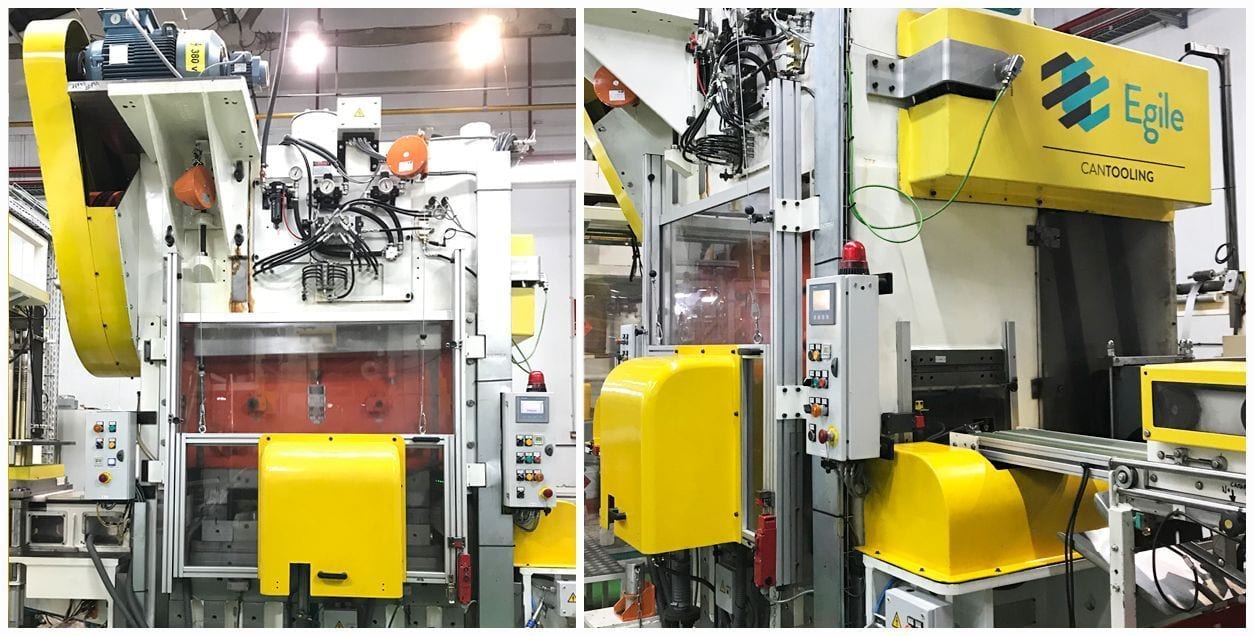

Egile has delivered new conversion systems and easy-open lid presses for the food sector, for the plant that Domiberia has in Vigo.

Domiberia is a company specialised in the metalworking sector, dedicated to the manufacture of metal containers and lids for the food, industrial and decorative markets, as well as a metal preparation centre (cutting, varnishing and printing).

The initial project consisted of the delivery of 2 easy-open presses and their conversion systems. In case of satisfactory results, the forecast would be to increase the number of complete presses, each one including different formats.

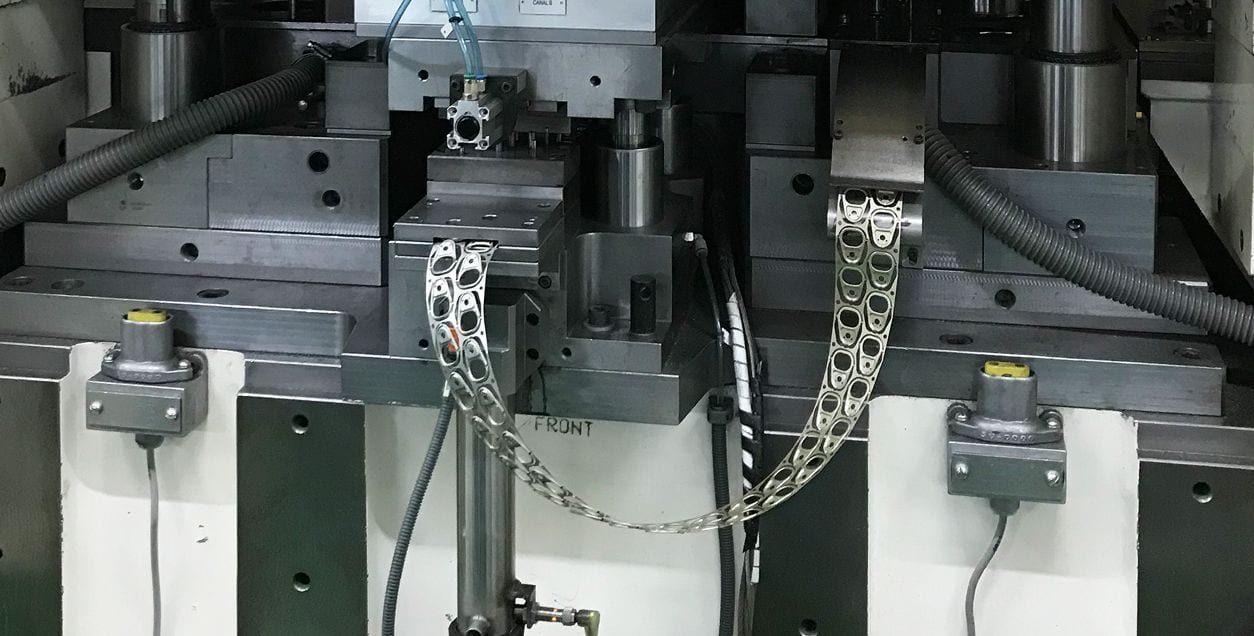

Egile embarks on this project with extensive experience in the design of high-precision dies for easy-open systems and their subsequent manufacture and assembly. With the internal efforts of the team and the continuous support and advice of the Domiberia team, we have managed to develop a complex product that few manufacturers are able to offer.

Challenge:

The challenge for Domiberia consisted in the modernization of its production means, both in terms of presses and conversions, together with a redesign of the final product and a new development of all the die-cutting inherent to the production process.

The project had to meet different objectives. On the one hand, the diversification of products, increasing the portfolio with the incorporation of a greater number of easy-open lid formats. Other objectives would be a significant increase in productivity and an improvement in the final product.

All this as a clear commitment to improving competitiveness, increasing and strengthening its presence in the food packaging market.

Solution:

Egile provides Domiberia with a customised solution that covers all your needs.

On the one hand, by providing experience in the conversion of the transmissions of circular presses into linear presses, reconditioning them in optimal working conditions for long periods of time.

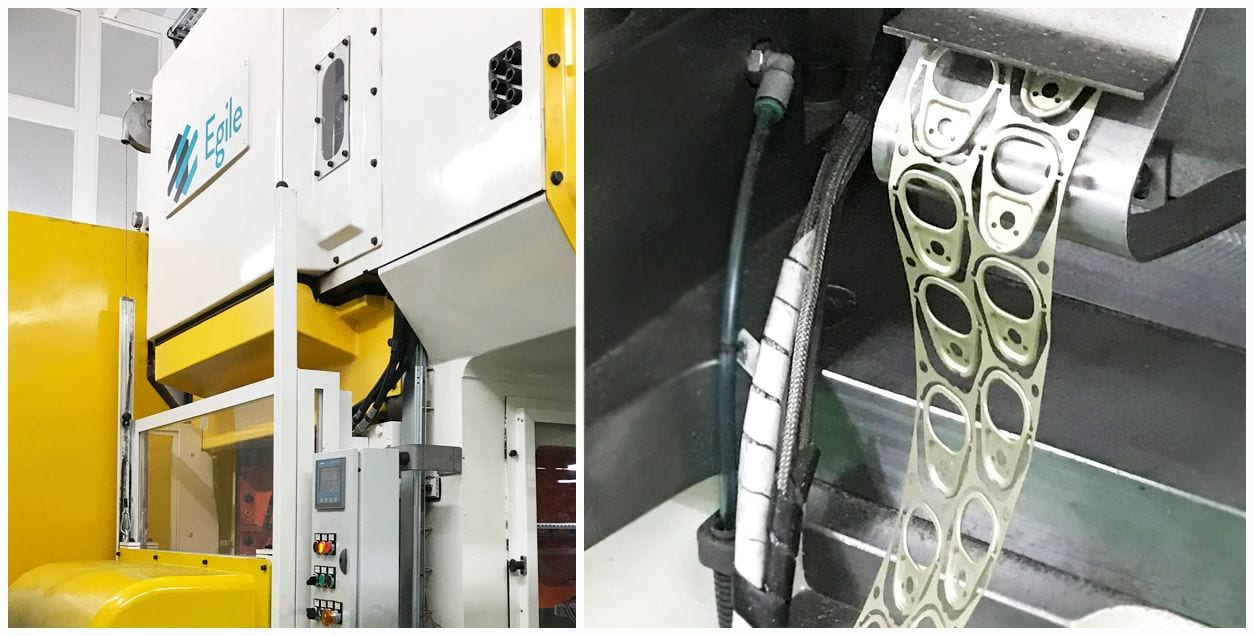

On the other hand, Egile offers a robust die product with high operational reliability, prepared to work at high and demanding working speeds (up to 500 strokes/min) and covering the stamping of different cap formats, both round and shaped.

This helps Domiberia in product diversification, offering a more efficient product, and in reducing its manufacturing costs. Also offering standardized ring level dies, which help with flexibility of use.

Today, the 2 initial systems are working at full capacity.

It is worth mentioning in this project professionals such as the current head of product design projects Ernai Solabarrieta, for his role in knowing the technical requirements of Domiberia and achieving solutions that meet the conditions of performance and quality. On the other hand, Ekhi Illarramendi and Mikel Meabebasterretxea, current product development engineer and assembly coordinator respectively, have carried out the construction and commissioning of the presses. Without them and without the close and active collaboration with Domiberia, it would not have been possible to achieve these technically demanding milestones.

Conclusion:

After a great effort and dedication over a long period of time by Egile and Domiberia, the milestones of development and implementation have been reached in a good part of the projects.

The joint project has helped and will help the latter to better position itself in the market, improving both its competitiveness and the equipment of its production plant.

“Egile has demonstrated a capacity for adaptation, flexibility, involvement and proximity, as differential factors. All this should ensure that we can count on Egile as a reliable supplier and present and future development”. (José Ángel Albolea (Plant Manager Domiberia Vigo)).