Description

- Decentralized control cabinets for optimum signal transmission and short reaction time

- New type of wickets “Double chrome tube wickets”.

- Less weight, more stability, no vibrations.

- Display of the solvent quantity in %.

- Gas consumption.

- Power consumption.

- Air consumption.

- Energy management according to DIN ISO 500001.

- Energy efficiency.

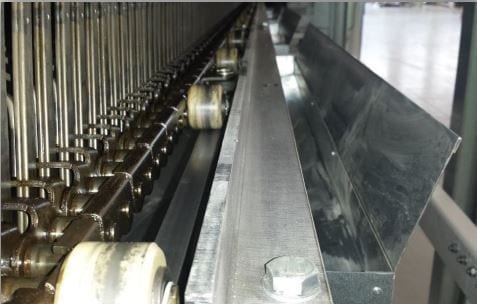

- New chain system (developed by HMD) with synthetic rollers and lateral chain guide, noise reduction.

- The new chain has a lower lubrication frequency, does not contaminate due to grease.

- Synthetic rollers last longer and have a longer service life compared to metal and carbon rollers.

- No more carbon energy inside the tunnel, no more pollution.

- Chain transport requires less electrical energy.

High productivity

- Larger air volume with a wider cross-section allows for quieter and more balanced air flow

- Wicket feed with dynamic braking system for smooth sheet loading

- Dynamic blade braking and acceleration systems to ensure smooth blade handling while maintaining perfect blade quality without damage.

- Production speed up to 8,000 sheets / hour.

Cooling zone

- The cooling zone provides optimal cooling airflow thanks to two high-performance radial fans

- FU Control for all fans

Easy to use

- Innovative monitoring scheme for easy control of the entire dryer.

- Memorization of job settings for fast and reliable reloading of repeated jobs

- Detailed comparison of target / actual value

- Real-time display of production parameters, such as gas consumption.

- % Solvent load inside the incinerator

Reviews

There are no reviews yet.